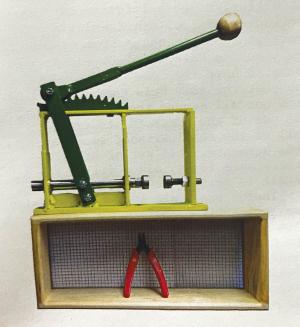

Heavy-Built Nutcracker Cracks Walnuts Quickly, Cleanly

✖  |

“The reason I built this nutcracker is that I’ve been cracking walnuts for 50 years but I’ve never been happy with any of the nutcrackers I’ve owned. I finally decided there had to be a better way,” says John Petersheim of J P Wood and Metal of Mifflintown, Penn.

He calls the well-built nutcracker “The New Style Black Walnut Cracker,” and it’s so simple to operate that “even older ladies and young children have no problem cracking walnuts with it.”

The steel nutcracker mounts on a 9 by 30-in. board. His invention is a little different than what might be typical because of the shape of the jaw holes used to crack the nut.

“Since the nuts are oval-shaped, the jaw holes needed to be oval as well,” he says. “Using a ball end mill on a milling machine, I experimented until I had jaws that worked well on the most common-sized walnuts.

“All of the outside shell cracks first,” Petersheim adds. “This method of cracking walnuts takes more force since it hits the entire shell at once, so the nutcracker has to be sturdy. Our nutcracker has a cracking force ratio of 185 to 1.”

The extra-long handle on each nutcracker makes it possible to stop at any point in the cracking process. You can go a little further if you wish to crack the center as well. “The best thing about it is that the nut meats come out whole,” says Petersheim.

He’s built 100 of the nutcrackers so far, and they sell for $115 each.

Contact: FARM SHOW Follwup, J P Wood and Metal, 99 Muskrat Springs Road, Mifflintown, Penn. 17059. No Phone Number.

Click here to download page story appeared in.

Click here to read entire issue

Heavy-Built Nutcracker Cracks Walnuts Quickly Cleanly FARM HOME Miscellaneous “The reason I built this nutcracker is that I’ve been cracking walnuts for 50 years but I’ve never been happy with any of the nutcrackers I’ve owned I finally decided there had to be a better way ” says John Petersheim of J P Wood and Metal of Mifflintown Penn He calls the well-built nutcracker “The New Style Black Walnut Cracker ” and it’s so simple to operate that “even older ladies and young children have no problem cracking walnuts with it ” The steel nutcracker mounts on a 9 by 30-in board His invention is a little different than what might be typical because of the shape of the jaw holes used to crack the nut “Since the nuts are oval-shaped the jaw holes needed to be oval as well ” he says “Using a ball end mill on a milling machine I experimented until I had jaws that worked well on the most common-sized walnuts “All of the outside shell cracks first ” Petersheim adds “This method of cracking walnuts takes more force since it hits the entire shell at once so the nutcracker has to be sturdy Our nutcracker has a cracking force ratio of 185 to 1 ” The extra-long handle on each nutcracker makes it possible to stop at any point in the cracking process You can go a little further if you wish to crack the center as well “The best thing about it is that the nut meats come out whole ” says Petersheim He’s built 100 of the nutcrackers so far and they sell for $115 each Contact: FARM SHOW Follwup J P Wood and Metal 99 Muskrat Springs Road Mifflintown Penn 17059 No Phone Number

To read the rest of this story, download this issue below or click

here to register with your account number.