1984 - Volume #8, Issue #2, Page #21

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

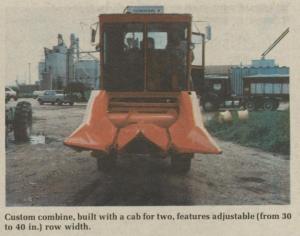

You've Never Seen A Combine Like This

|

The feature is installed on smaller 2 and 3-row combines used for harvesting hybrid seed corn. It allows the operators to switch "on the go" from 30 to 40-in. widths, or anywhere in between. The idea can also be used on forage harvesters and, in fact, one company has already bought rights from Lindquist for custom harvesting machines so custom operators can move from farm to farm without worrying about changing heads. On plot combines the reasoning is the same.

"People don't realize how big and varied the seed corn growing business is. There are plots in every geographic area. Last year, two custom operators who own a 2-row machine we built harvested just 60 acres during the season but traveled 28,000 miles," says Lindquist.

Many farmers are now planting their corn and soybean crops at the same width. This wouldn't be necessary if the adjustable head design were adapted to full-size machines, Lindquist notes. "It would also allow custom combiners to work in different row widths with just one header.

"The problem with adapting this idea to larger heads is that the feeder auger will stick out from the side of the head if you get over 3 rows. We have to figure out a way to fold up the auger," Lindquist told FARM SHOW.

To build the adjustable header, Lindquist takes a conventional head and modifies the tinwork and mounting apparatus, building either 2 or 3-row heads. The row units slide on a framework and the feeder auger is the only part that doesn't compress but remains under the framework on the sides. The header is controlled by a control in the cab and there's an inch scale on the back of the head so you can see the width from the cab.

The unique combines have hydrostatic drive, a dual operator cab, air conditioning, dual heaters, a flow-through moisture tester, and a hydraulic unloading batch scale. Lindquist says the two most popular combines he modifies for plot work are the E Gleaner and the 26 Massey.

For more information, contact: FARM SHOW Followup, Lindquist Welding & Supply, Box 37, Giltner, Neb. 68841 (ph 402 849-2264).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.