1993 - Volume #17, Issue #2, Page #06

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

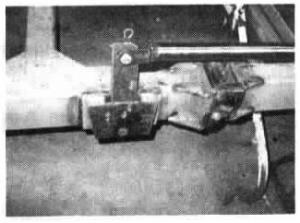

46 1/2 ft Folding Feld Cultivator

|

|

The cultivator has a 20-ft. center section and two 13-ft. wings. Dewey used 4 by 6 steel tubing to build the cultivator frame and 4 by 8 tubing to build the tongue. He used 2 1/4 in. sq. tubing for the crossbars. There's 20-in. spacing between shanks. Wings are folded by two 4 by 24-in. hydraulic cylinders. A Buster Bar harrow and a 5-bar drag harrow are mounted on back. There's also room for a sprayer boom.

"It's built heavy and lets me cover a lot of acres fast," says Dewey. "I use a 300 hp IH 4568 4-WD tractor to pull it. I had been using a 25-ft. disk, but I wanted to switch to a field cultivator because I knew it would do a better job of fluffing up the ground and incorporating pre-plant herbicides. It also doesn't pack the soil as much. However, I couldn't find a field cultivator over 30 ft. wide. Most of the ones on the market are smaller and built too light.

"I looked at a lot of cultivator models and used their best features to build my own. For example, the cultivator's four rows of shanks were designed for an International 45 Vibra Shank cultivator. I copied the center transport axle design off an International 490 disk.

"It's built good and level because while building it I used a transit rod to keep the center section and wings level. I spent only about $8,000."

Contact: FARM SHOW Followup, John Dewey, Rt. 1, Box 10, Penfield, Ill. 61862 (ph 217 595-5535).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.