Sliding Roof Fertilizer Shed

Abe Derstine, a dairy farmer in Northeastern Pennsylvania, uses over 65,000 lbs. of fertilizer each year. He used to buy it in 80 lb. bags ù about 8,000 of them. It was expensive and handling the bags required a lot of manual labor.

Abe thought there had to be a better way. He found that better way ù a pole shed with a sliding roof to permit a large dump truck to drive inside and dump the load of fertilizer.

Derstine had local general contractor, Wilmer Allgyer, of Rome, Pa., draw up a few rough sketches of the idea. No formal plans were drawn up.

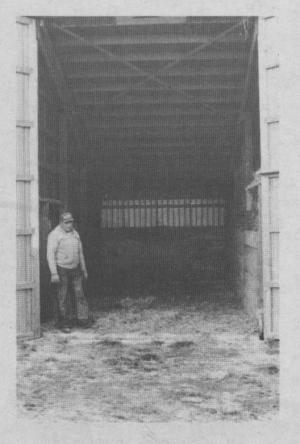

What Allgyer built for Derstine was basically a pole barn structure 50 ft. wide, 30 ft. deep, 18 ft. high in front and 9 ft. high at the rear. The building was divided into four equal bays with 5 ft. high partitions extending the entire depth of the building, except for a 2 ft. wide opening at the front to allow access to the bays.

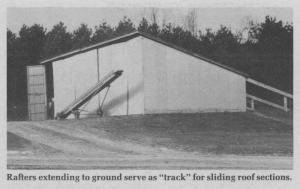

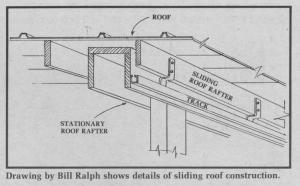

The sliding roof is divided into two sections with a slight overlap where the two sections meet to keep out rain and snow. The roof is supported by five massive stationary box rafters to which the metal track is fastened. These rafters extend beyond the building, almost to the ground.

The sliding mechanism consists of two tracks for each roof section. The tracks are conventional hanging barn door box tracks but installed upside down with special hardware. The trolleys (wheels) on the track are connected to the sliding roof structure. Center rafters of each sliding section have no track but are heavily greased to allow the sliding roof to slide directly on the rafter.

Each roof section is held in place with a steel cable fastened to a silo winch near the front of the building. A portable 3/4 in. drill motor is used to turn the winch. "First we tried a small hand-operated boat winch," says Derstine. "But the roof sections were much too heavy for that."

Access to the front of each bay is by two 6 ft. by 18 ft. swinging doors. The doors are secured by drop latches near the floor and by spring-loaded chain-pull latches near the top. As protection against the strong winds, a sliding latch made from a 2x4 secures each set of doors. A strip of wood along the front edge of the sliding roof limits the inward travel of the doors when the roof is closed. Since the tall doors are secured from the inside, a small entrance door is provided at the side of the building.

The floor of the building is a slab of 4-inch concrete. A polyurethane sheet was laid down before the concrete was poured to keep out moisture. The sides and roof of the building are covered with Wheeling galvanized Channel Drain sheet metal.

When in use, each bay is loaded with a different kind of fertilizer. One formula is used for plowdown, another for planting, and a third for top dressing hay fields. The fourth bay is intended for the storage of lime. In winter, when the building is empty, Derstine uses it to store hay.

For more details, contact: FARM SHOW Followup, Abe Derstine, Rt. 1, Athens, Pa. 18810 (ph 717 247-7397).

Click here to download page story appeared in.

Click here to read entire issue

Sliding roof fertilizer shed BUILDINGS New Techniques 9-2-3 Abe Derstine, a dairy farmer in Northeastern Pennsylvania, uses over 65,000 lbs. of fertilizer each year. He used to buy it in 80 lb. bags ù about 8,000 of them. It was expensive and handling the bags required a lot of manual labor.

Abe thought there had to be a better way. He found that better way ù a pole shed with a sliding roof to permit a large dump truck to drive inside and dump the load of fertilizer.

Derstine had local general contractor, Wilmer Allgyer, of Rome, Pa., draw up a few rough sketches of the idea. No formal plans were drawn up.

What Allgyer built for Derstine was basically a pole barn structure 50 ft. wide, 30 ft. deep, 18 ft. high in front and 9 ft. high at the rear. The building was divided into four equal bays with 5 ft. high partitions extending the entire depth of the building, except for a 2 ft. wide opening at the front to allow access to the bays.

The sliding roof is divided into two sections with a slight overlap where the two sections meet to keep out rain and snow. The roof is supported by five massive stationary box rafters to which the metal track is fastened. These rafters extend beyond the building, almost to the ground.

The sliding mechanism consists of two tracks for each roof section. The tracks are conventional hanging barn door box tracks but installed upside down with special hardware. The trolleys (wheels) on the track are connected to the sliding roof structure. Center rafters of each sliding section have no track but are heavily greased to allow the sliding roof to slide directly on the rafter.

Each roof section is held in place with a steel cable fastened to a silo winch near the front of the building. A portable 3/4 in. drill motor is used to turn the winch. "First we tried a small hand-operated boat winch," says Derstine. "But the roof sections were much too heavy for that."

Access to the front of each bay is by two 6 ft. by 18 ft. swinging doors. The doors are secured by drop latches near the floor and by spring-loaded chain-pull latches near the top. As protection against the strong winds, a sliding latch made from a 2x4 secures each set of doors. A strip of wood along the front edge of the sliding roof limits the inward travel of the doors when the roof is closed. Since the tall doors are secured from the inside, a small entrance door is provided at the side of the building.

The floor of the building is a slab of 4-inch concrete. A polyurethane sheet was laid down before the concrete was poured to keep out moisture. The sides and roof of the building are covered with Wheeling galvanized Channel Drain sheet metal.

When in use, each bay is loaded with a different kind of fertilizer. One formula is used for plowdown, another for planting, and a third for top dressing hay fields. The fourth bay is intended for the storage of lime. In winter, when the building is empty, Derstine uses it to store hay.

For more details, contact: FARM SHOW Followup, Abe Derstine, Rt. 1, Athens, Pa. 18810 (ph 717 247-7397).

To read the rest of this story, download this issue below or click

here to register with your account number.