1990 - Volume #14, Issue #2, Page #07

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

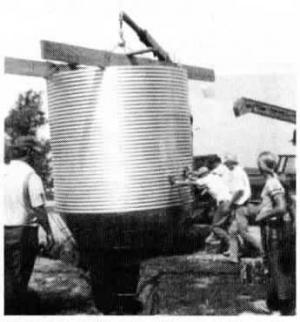

Build Grain Dump Pit

|

Ochsner dug a hole in the ground with a backhoe and then dug a trench for a load-out auger running diagonally from the bottom of the hole to the soil surface. He used a crane mounted on a truck to lower the tank into the hole. Then he filled the tank with grain so it would stay in place while he poured cement around it. After the concrete had set, he used a grain vacuum to suck the grain out of the tank. Then he removed the tank and laid a 22-ft. long, 6-in. dia. auger (inside an 8 5/8-in. steel tube) from the bottom of the pit to the above-ground auger.

Ochsner dismantled the tank before removing it from the hole. "Before we lowered the tank into the hole we hand tightened the bolts so we knew we'd be able to take the tank apart in sections," says Ochsner, who built the dump pit 14 years ago. "The auger is powered by a 5 hp electric motor and delivers grain into another auger that's used to move grain into storage."

The 580-bu. dump pit cost $4,000 to build. "A conventional dump pit would've cost at least $10,000," notes Ochsner.

Contact: FARM SHOW Followup, Gerald Ochsner, RR 2, Box 3B, Sutton, Neb. 68979 (ph 402 773-5216).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.