1995 - Volume #19, Issue #4, Page #29

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

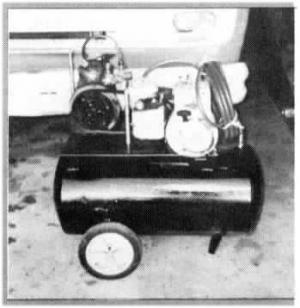

Gas Engine-Driven Air Compressor

|

Schmidt had previously sold auto air compressors and knew they could pump well over 300 psi. And they knew salvage yards were full old style Ford compressors in perfectly good shape.

So when his compessor wore out, he mounted an automotive air conditioner compressor and powered it with the original electric motor.

After seeing how well it worked, he got the idea of building something he'd always wanted but could never justify - a gas powered, "truly portable" compressor. He mounted another AC compressor with a head valve on a used air tank he bought. Then he put a used Briggs & Stratton gas engine on the tank to drive it. He had to buy a by-pass valve that would kick in at about 100 psi. It cost $35 at a local hardware store. Total cost of the gas-powered compressor was about $90, compared to $500 or more for a new one, says Schmidt.

"I can't tell any difference between these two tanks and commercial one. The gas on is great because you can use it in the field. You could make your own from scratch using a 12-gal, air tack, which you can buy at Walmart for about $35,"

Conta t: FARM SHOW Followup, Mike Schmidt, 112 Gaynelle Lane, Hobart, Okla. 73651 (ph 405 726-3213).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.