2013 - Volume #37, Issue #5, Page #20

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

]

Wooden Headgate Simple, Quiet

|

|

“I remember as a boy pulling the rope to shut the headgate on a cow as my dad pushed her down the chute,” says Laughbaum. “I would hold the chute shut till my dad could insert a steel pin to lock it.”

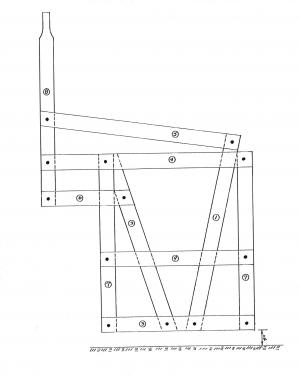

The headgate is a simple affair of 2 by 4’s that operate on a scissoring action. It works well with a chute design that has a swing gate to its side for cattle to exit the chute once freed from the headgate.

“The headgate has an overall width of 42 in. and a height of 70 in.” says Laughbaum. “It’s made from rough-cut hardwood 2 by 4’s and 1/2-in. bolts. It probably wouldn’t cost more than $75 in wood at a sawmill.”

The headgate consists of 2 uprights, 3 single crossbars and 2 pairs of crossbars. It‘s mounted to posts sunk in the ground at the end of the chute. Mounting carriage bolts extend through the uprights, crossbars and the posts.

The first crossbar is mounted at the top of the frame, and the second is 11 1/2 in. lower. A pair of crossbars is mounted 14 1/2 in. below the second crossbar with a second pair mounted 22 in. lower, providing room for the animal’s head. This pair is 56 in. long and extends past the right upright of the headgate to serve as a mount and pivot point for the headgate control bar. The final crossbar is mounted 14 1/2 in. lower at the bottom of the uprights.

The sliding bars that close around the animal’s head ride between the two crossbar pairs. When open, they form a V with their bottom ends bolted to the lowest crossbar on the headgate frame and 14 1/2 in. from either upright.

Laughbaum stresses that the geometry of the sliding bar and the control bar is important. When the control bar is vertical, the headgate is open. When it leans away from the headgate, the headgate is closed.

“Initially, the lock pin hole was in wood,” says Laughbaum. “My dad added a 4-in. wide steel plate when the hole in the wood got worn and loose. The plate has 5 holes in it to adjust to different size cattle.”

Today, Laughbaum uses his headgate for a small herd on his hobby farm. “Our veterinarians really like it,” he says. “They say it’s quieter than steel headgates and doesn’t spook the cattle.”

Laughbaum says his father first saw similar headgates while working on a government ranch in Idaho during WWII.

Plans are currently available online at http://msucares.com/pubs/plans/5778a.pdf.

Contact: FARM SHOW Followup, Chuck Laughbaum, 2251 Pleasantview Rd., Pellston, Mich. 49769 (ph 231 539-8906).

Click here to download page story appeared in.

To read the rest of this story, download this issue below or click here to register with your account number.