1977 - Volume #1, Issue #5, Page #01

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Get Set To Turn Straw Into Money

|

|

|

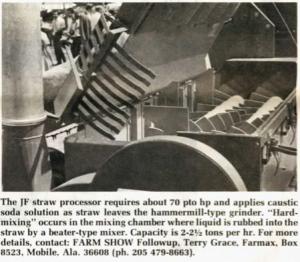

One of the biggest breakthroughs in the long search for a practical, economical way to boost the nutritional value of straw and other low quality roughages is the J-F Fabriken portable processor. Developed in Denmark and designed exclusively for processing straw, it’s one of several new straw processing machines making headlines in farm magazines throughout Europe. The J-F processor has passed extensive field trials and feeding tests with flying colors and is already in commercial production, with customers waiting in line to grab units as fast as they roll off the assembly line.

“We’re hoping to get one or two machines shipped to the U.S. within the next several months,” reports Terry Grace, president of Farmax, Mobile, Ala. His company handles sales of J-F Fabriken equipment in the U.S.

“We think the new J-F straw processor has great potential for turning straw into money,” Grace told FARM SHOW. He anticipates that the machine will sell in the U.S. in the $15,000 to $18,000 range.

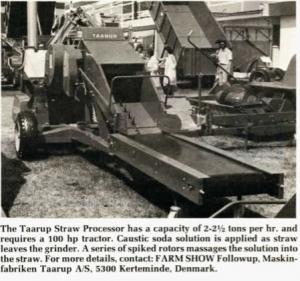

Two other popular straw processing machines in Europe are the Taarup, manufactured by Maskinfabrken Taarup, A/S, 5300 Kerteminde, Denmark, and Farmland’s Feed Processor.

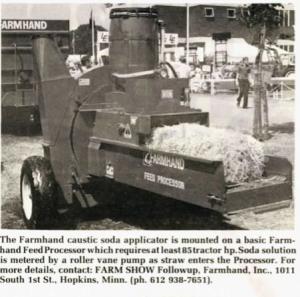

A spokesman for Farmhand, head-quartered in Hopkins, Minn., told FARM SHOW that limited straw-processing trials are underway in the U.S. but most of the work to date has been done by representatives of Farmhand’s independent marketing organization in England. They’ve equipped the Feed Processor with a special device for applying caustic soda on straw as it’s processed in the machine.

Straw processing machines now being sold in Europe have capacities of 2 to 3 1/2 tons per hour. Straw is finely ground (1 to 1 1/4 in. long) and treated with approximately one gallon of 30% sodium hydroxide solution per 100 lbs. of straw dry matter. This treatment has been shown to raise its feeding value to levels comparable to good grass hay or grass silage, and to about 70% the feeding value of barley.

Recommendations vary but feeding of processed straw can usually start about three to eight days following treatment. Treated straw is eaten willingly by animals. Adult cattle will eat 10 to 20 lbs. of processed straw per day, depending on the crude fiber content of other feed components. This means that as much as half the roughage of dairy cattle may be processed straw, and up to two-thirds of the roughage for young stock and beef cows. Processed straw is, however, very low in protein and must be properly supplemented to provide an adequate ration.

Processed straw is easily handled by silage equipment or front end loaders, and is easily mixed with silage and concentrates for complete ration feeding.

Processed straw must be kept dry but does not require special storage conditions or structures. It’s high pH (8-8.5) retards activity of bacteria and fungi so spoilage is not a problem. Coverage with plastic is not recommended. Some farmers have stored processed straw in the bottom of vertical silos to absorb the highly nutritious juices which normally seep out of regular silage placed about it.

Here, according to Henning Pederson of the J-F Fabriken Co., is how his company’s new processor, designed to process straw bales, works:

Individual bales are placed on the feeder table. While the bale is being chopped, it is kept in position by a holder plate above it and a grate. Finger knives in the chopper cut a number of tracks in the bale. The effect is comparable to 20 circular saw blades cutting through a straw bale. After chopping, the straw passes through a system of finger shearbars, ensuring that all straw in the bale is chopped in short pieces.

The special chopping system splits most of the straw lengthwise so that the liquid mixture of sodium hydroxide can be applied to the inner side of the straw. The liquid is sprayed on as straw leaves the chopper and falls into the mixing vessel.

“After three days and three nights of storage, digestibility is close to maximum and feeding can start,” says Pederson. “The processed and treated straw is very compact, with from 2 to 4 times as much density as regular untreated straw bales.”

For more details on straw processing equipment, contact the manufacturers of the recently-introduced processing equipment shown in the accompanying photos.

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.