Loader Mounted Round Bale Saw

✖  |

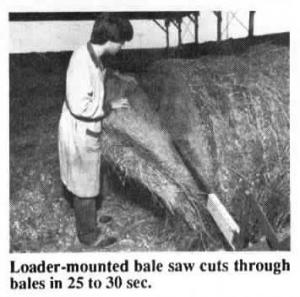

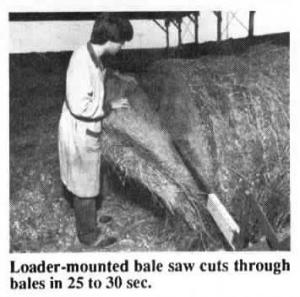

A prototype, hydraulic-powered round bale cutter mounted on a front-end loader makes it easier to cut up round bales and feed them to livestock in confined spaces, according to engineers at the University of Guelph, Guelph, Ontario.

W.K. Bilanski originally developed the giant bale saw to open round bales for quality evaluation. It worked so well they decided to evaluate it as an aid for feeding bales. They built a frame that allows the cutter to be mounted on a front-end loader. It's powered by the tractor's hydraulic system.

"It cuts through bales clean as a whistle in 25 to 30 seconds," says Bilanski. "A single cut down the length of the bale opens it up into a stack of loose hay which can easily be fed with a fork. It's best to cut the bale lengthwise because only a slight downward force on the cutter is needed. Cutting it sideways takes up to twice as long and requires much more force. A bale handling device could be mounted behind the tractor which would allow the same tractor to move the bale into the feeding area and open it up. It could also be mounted on a gantry in a feedroom adjoining a tie stall barn. A tractor would place the bale in the feedroom, and the cutter would swing over the bale and split it open. It could be powered electrically with a self-contained hydraulic system."

The engineers used an industrial sickle-bar designed to cut paper to build the bale saw. They replaced the cutterbar on the unit with their own 7-ft. 3 in. long, 4-in. wide, 3/ 4-in. thick sicklebar. The cutting edge is a 1 in. wide bandsaw blade with 3 teeth per inch. The blade is clamped in a sheet metal holder and is connected to the pitman drive of the original cutter which provides a reciprocating motion with a knife stroke of 2 1/2 in.

"The cutter performs best at 1,070 cycles per minute," says Bilanski. "If adequate hydraulic flow and pressure were available, a higher rate of reciprocation would improve cutting efficiency. At slower speeds the knife tends to shake the bale rather than starting the cut."

Bilanski notes that the length of the tractor and blade may be too long for confined areas. "Replacing the pitman with a wobble drive would reduce the overall length." The cutter should be fitted with a shield when not in use, he adds.

For more information, contact: FARM SHOW Followup, W.K. Bilanski, University of Guelph, School of Engineering, Guelph, Ontario, Canada N1G 2W1 (ph 519 824-3923).

Click here to download page story appeared in.

Click here to read entire issue

Loader Mounted Round Bale Saw HAY & FORAGE HARVESTING Bale Handling (5) 15-2-4 A prototype, hydraulic-powered round bale cutter mounted on a front-end loader makes it easier to cut up round bales and feed them to livestock in confined spaces, according to engineers at the University of Guelph, Guelph, Ontario.

W.K. Bilanski originally developed the giant bale saw to open round bales for quality evaluation. It worked so well they decided to evaluate it as an aid for feeding bales. They built a frame that allows the cutter to be mounted on a front-end loader. It's powered by the tractor's hydraulic system.

"It cuts through bales clean as a whistle in 25 to 30 seconds," says Bilanski. "A single cut down the length of the bale opens it up into a stack of loose hay which can easily be fed with a fork. It's best to cut the bale lengthwise because only a slight downward force on the cutter is needed. Cutting it sideways takes up to twice as long and requires much more force. A bale handling device could be mounted behind the tractor which would allow the same tractor to move the bale into the feeding area and open it up. It could also be mounted on a gantry in a feedroom adjoining a tie stall barn. A tractor would place the bale in the feedroom, and the cutter would swing over the bale and split it open. It could be powered electrically with a self-contained hydraulic system."

The engineers used an industrial sickle-bar designed to cut paper to build the bale saw. They replaced the cutterbar on the unit with their own 7-ft. 3 in. long, 4-in. wide, 3/ 4-in. thick sicklebar. The cutting edge is a 1 in. wide bandsaw blade with 3 teeth per inch. The blade is clamped in a sheet metal holder and is connected to the pitman drive of the original cutter which provides a reciprocating motion with a knife stroke of 2 1/2 in.

"The cutter performs best at 1,070 cycles per minute," says Bilanski. "If adequate hydraulic flow and pressure were available, a higher rate of reciprocation would improve cutting efficiency. At slower speeds the knife tends to shake the bale rather than starting the cut."

Bilanski notes that the length of the tractor and blade may be too long for confined areas. "Replacing the pitman with a wobble drive would reduce the overall length." The cutter should be fitted with a shield when not in use, he adds.

For more information, contact: FARM SHOW Followup, W.K. Bilanski, University of Guelph, School of Engineering, Guelph, Ontario, Canada NiG 2W1 (ph 519 824-3923).

To read the rest of this story, download this issue below or click

here to register with your account number.