1984 - Volume #8, Issue #5, Page #34

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

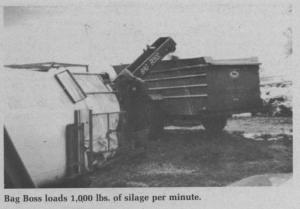

Mechanical Unloader For Plastic Silage Bags

|

"We think it's the biggest breakthrough in silage making since the relatively new concept of stuffing silage into long plastic bags was first introduced," says John Burgers, owner of John's Welding and Manufacturing of Inwood. He built the first prototype and is now "tooled up" to manufacture and market the mechanical unloader which was invented and patented by Vernon V. Johnson, of Galva.

Called the Bag Boss, it'll unload any plastic bag regardless of which make of machine ù Silo Press, Ag Bag, Max-Pac, Roto-Press or whatever ù does the ensiling. "So far, we've only tested the Bag Boss on haylage and silage. But we think it'll handle anything you can ensile in long plastic bags, whether it's corn silage, haylage, stalklage, ground ear corn, shelled corn or whatever," Burgers told FARM SHOW. As it eats its way into a pile of bagged silage, the Bag Boss scrapes the plastic clean. Power-driven rollers around the outer circumference gather in the plastic, keeping it intact and automatically folding it "accordian style" on a large spool for reuse.

"We anticipate that most bags unloaded within 12 months or so after filling can be reused several times," says Burgers. "However, even after longer-term storage, where the plastic has deteriorated too much for re-use, the Bag Boss automatically gathers in the plastic, keeping it out of the silage as the bag is unloaded."

Burgers notes that one man can operate the Bag Boss. "And, the same tractor used to pull the silage wagon you're loading into can be used to power the hydraulically-operated Bag Boss, which uses a cable to winch its way through the pile. It unloads the bag slick and clean, leaving no spilled silage to clean up afterwards.

"Another advantage of the Bag Boss is that, if it's muddy, the machine will unload an entire pile of bagged silage without leaving any deep ruts, as can happen when using a big tractor and loader to do the unloading," Burgers points out.

It takes the Bag Boss five to six hours to eat its way through a long plastic bag of silage measuring 150 ft. long and 9 ft. in dia., which figures out to about 1,000 lbs. of silage per minute. The machine can be steered, as needed, to direct it through piles with curves or bends in them.

"It only takes about 20 to 30 minutes to set up the Bag Boss and have it in operation," says Burgers. "You simply open up the tied end of the long plastic bag and thread it through the rollers and onto the machine's take-up spool. If the bag is filled way to the end, you may have to peel off a small amount of silage by hand to get the plastic threaded."

The machine, which converts to road transport in a matter of minutes, sells for right at $12,500. The prototype is a 9 ft. dia. model. Custom-built production models will be available for either 8 or 9 ft. dia. plastic bags. A self-propelled model equipped with a gas engine is in the hopper.

For more information, contact: FARM SHOW Followup, John's Welding and Manufacturing, John Burgers, Owner, P.O. Box 43, Inwood, Iowa 51240 (ph 712 753-4456).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.