Microwave Transforms Trash Into Fuel

Microwaves can be used for a lot more than popping corn or warming soup. Global Resource Corp. (GRC) is using microwave emitters to make fuel out of everything from tires and oil shale to biomass and plastics. GRC estimates their prototype one-ton system will process 10 tons of tires, plastics or vinyl per hour into 17 million btu's of energy, with an 18:1 return on energy used in the process. And since it all takes place in a vacuum, nothing is released into the environment.

"It doesn't take more energy to process oil shale, tires or coal, but the output varies," explains Jeff Kimberly, GRC. "The energy ratio depends on the size of the system. A bigger unit will require more and bigger pumps and more energy, but the output will be greater because it can handle more material."

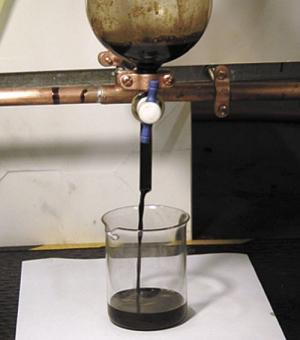

GRC plans to build 5, 10 and 15-ton systems once the prototype has proven itself. Regardless of size, the heart of the unit is the microwave emitters. When company founder Frank Pringle first experimented with bits of tire and microwaves, they turned into ash. However, when the gasses inside the microwave condensed, they created a black puddle of oil.

According to Pringle, the microwaves crack the molecular chains of hydrocarbon molecules. The molecules are broken into carbon black and hydrocarbon gases, which can be burned or condensed into liquid fuels.

Ten years and a million dollars later, GRC's one-ton unit is turning a wide variety of carbon-based materials into oil. As material is augered into and through a vacuum chamber, it's bombarded with microwaves. Gasses and water vapor are pulled out the top, and carbon black is augered out the end for further processing.

The key is to find the specific frequency for the material being processed. Frequencies for high return materials like plastics, tires, oil sand, oil shale and even coal have already been identified. According to GRC, a 20-lb. tire can produce 1.2 gal. of no. 4 oil, 50 cubic ft. (3,000 btu) of natural gas, 2 lbs. of steel and 7 1/2 lbs. of carbon black.

"We've started testing corn stalks, grass clippings, and other crop material," he says. "We're also looking at biofuel potential in sludge. There's not much we don't look at."

Contact: FARM SHOW Followup, Global Resource Corporation, Bloomfield Business Park, 408 Bloomfield Dr., Unit 3, West Berlin, N.J. 08091 (ph 856 767-5661; inquire@ globalresourcecorp.com; www.global resourcecorp.com).

Click here to download page story appeared in.

Click here to read entire issue

Microwave Transforms Trash Into Fuel ENERGY Alternative Fuels 32-3-4 Microwaves can be used for a lot more than popping corn or warming soup. Global Resource Corp. (GRC) is using microwave emitters to make fuel out of everything from tires and oil shale to biomass and plastics. GRC estimates their prototype one-ton system will process 10 tons of tires, plastics or vinyl per hour into 17 million btu's of energy, with an 18:1 return on energy used in the process. And since it all takes place in a vacuum, nothing is released into the environment.

"It doesn't take more energy to process oil shale, tires or coal, but the output varies," explains Jeff Kimberly, GRC. "The energy ratio depends on the size of the system. A bigger unit will require more and bigger pumps and more energy, but the output will be greater because it can handle more material."

GRC plans to build 5, 10 and 15-ton systems once the prototype has proven itself. Regardless of size, the heart of the unit is the microwave emitters. When company founder Frank Pringle first experimented with bits of tire and microwaves, they turned into ash. However, when the gasses inside the microwave condensed, they created a black puddle of oil.

According to Pringle, the microwaves crack the molecular chains of hydrocarbon molecules. The molecules are broken into carbon black and hydrocarbon gases, which can be burned or condensed into liquid fuels.

Ten years and a million dollars later, GRC's one-ton unit is turning a wide variety of carbon-based materials into oil. As material is augered into and through a vacuum chamber, it's bombarded with microwaves. Gasses and water vapor are pulled out the top, and carbon black is augered out the end for further processing.

The key is to find the specific frequency for the material being processed. Frequencies for high return materials like plastics, tires, oil sand, oil shale and even coal have already been identified. According to GRC, a 20-lb. tire can produce 1.2 gal. of no. 4 oil, 50 cubic ft. (3,000 btu) of natural gas, 2 lbs. of steel and 7 1/2 lbs. of carbon black.

"We've started testing corn stalks, grass clippings, and other crop material," he says. "We're also looking at biofuel potential in sludge. There's not much we don't look at."

Contact: FARM SHOW Followup, Global Resource Corporation, Bloomfield Business Park, 408 Bloomfield Dr., Unit 3, West Berlin, N.J. 08091 (ph 856 767-5661; inquire@ globalresourcecorp.com; www.global resourcecorp.com).

To read the rest of this story, download this issue below or click

here to register with your account number.