Stud Installer Tool

✖  |

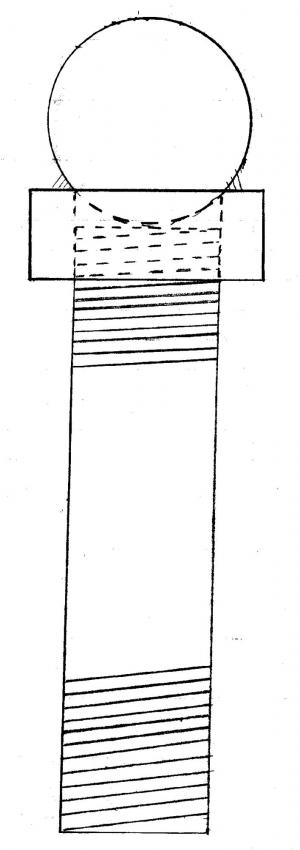

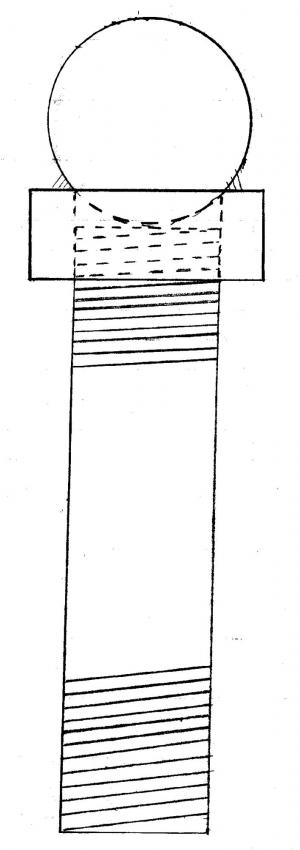

Galen Vestal, Montesano, Wash.: "I was a heavy equipment mechanic for years and made this stud installer tool when I was working on the Alaska pipeline a few years ago. A lot of equipment there had planetary gears in the drive wheels. My stud installer lets me use an impact wrench to quickly set the stud. The stud won't loosen when the installer nut is spun off. You simply weld an old discarded ball bearing into the nut, welding all the way around on one side of the stud (the studs are fine on one side and rough on the other side). Then screw the stud into the nut until it seats itself against the center of the bearing. The job ordinarily takes a long time to do by hand, but using an impact wrench saves a lot of time. When you reverse the nut it won't suck the stud up out - it brings the nut off the end of the stud without bringing the stud up. With the ball bearing in the nut, the only surface area it's touching is right on the end. I used this idea when I had a lot of broken 9/16-in. bolts on my front-end loader. I had to remove all of them and put in new ones. The only alternative is to screw on a double nut so tight that it could jimmy the threads or draw the stud back out and lose the torque value."

Click here to download page story appeared in.

Click here to read entire issue

Stud Installer Tool FARM SHOP Handy Hints 20-1-31 Galen Vestal, Montesano, Wash.: "I was a heavy equipment mechanic for years and made this stud installer tool when I was working on the Alaska pipeline a few years ago. A lot of equipment there had planetary gears in the drive wheels. My stud installer lets me use an impact wrench to quickly set the stud. The stud won't loosen when the installer nut is spun off. You simply weld an old discarded ball bearing into the nut, welding all the way around on one side of the stud (the studs are fine on one side and rough on the other side). Then screw the stud into the nut until it seats itself against the center of the bearing. The job ordinarily takes a long time to do by hand, but using an impact wrench saves a lot of time. When you reverse the nut it won't suck the stud up out - it brings the nut off the end of the stud without bringing the stud up. With the ball bearing in the nut, the only surface area it's touching is right on the end. I used this idea when I had a lot of broken 9/16-in. bolts on my front-end loader. I had to remove all of them and put in new ones. The only alternative is to screw on a double nut so tight that it could jimmy the threads or draw the stud back out and lose the torque value."

To read the rest of this story, download this issue below or click

here to register with your account number.