2006 - Volume #30, Issue #6, Page #37

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Advice On Buying A Waste Oil Heater

|

He says that if you follow a few simple rules, you can avoid most problems and really benefit your pocket book.

"First get references from a user in your area," says Thompson. "Don't buy based on a magazine ad or flyer.

"Second, deal with a reputable company that has been in the business a while."

He sells Reznor waste oil furnaces, but performs maintenance on a wide variety of others including Black Gold, Clean Burn, Shenandoah, Lanair and Omni. "If you don't know who is producing a good furnace, go to businesses that produce a lot of waste oil and burn it themselves," he suggests. "Find out who they bought from and how it's working out."

Thirdly, he says you should always buy through a dealer to get the right furnace and to get it installed properly. "Proper installation takes care of the most serious potential problems," he notes.

Thompson learned about waste oil furnaces the hard way. As an owner of a service station and automotive repair shop in the early 1980's, he had plenty of waste oil to dispose of. The first two furnaces he bought didn't work out. As he fixed them, he became familiar with how they worked. Today, his Oregon Commercial Heating company services and repairs 1,200 to 1,400 waste oil furnaces on an annual schedule and another 1,700 on an emergency basis.

"A lot of companies sell waste oil furnaces, but don't service them," he says. "Waste oil burners need to be cleaned regularly so they will burn efficiently. There are many different waste oil furnaces, a ton of different types of equipment, and lots of them don't work very well."

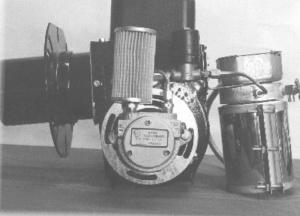

Rather than simply replace poorly functioning parts, Thompson has developed his own burner, metering pump and heat exchanger that install into existing units.

"We borrowed ideas from all the different equipment we sell and service," he says. "This way our customers don't have to buy a new furnace or spend a lot of time trying to adjust equipment that doesn't work properly."

Thompson notes that due to the sulfides in waste oil and the high temperatures involved, heat exchangers and combustion chambers tend to burn out faster than the rest of the furnace.

To keep equipment operating properly, Thompson suggests getting regular service from someone who knows codes for installing equipment, including Class A high temperature chimneys. He points out that improper installation could cancel insurance coverage if it results in a fire.

Quality of fuel is also important. He emphasizes storing waste oil by itself and avoiding the accidental addition of antifreeze or water. He suggests a minimum tank size of 500 gal. with secondary containment and a drain valve.

"Crack the drain valve periodically, and dribble out what water is there," he says. "If at all possible, filter waste oil before it goes into the tank. If contaminants get into the tank, they will create a sludge that has to be removed at some point."

Avoiding sludge is why Thompson also recommends against mixing greases and gearbox oils with acceptable waste oil. "Some companies claim they can burn grease and gear box oil, but most of it will just drain to the bottom of the tank," he says.

Thompson suggests limiting waste oils to motor oil, cooking oils, hydraulic oil, transmission fluid, combustible synthetic oils, and any other oil up to 50 S.A.E.

Contact: FARM SHOW Followup, Oregon Commercial Heating, 9684 S Wildcat Rd., Molalla, Ore. 97038 (ph 503 829-9670; fax 503 829-9684; sales@oregoncommercialheating.net; www.oregoncommercialheating.net).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.