1978 - Volume #2, Issue #2, Page #07

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Circle Plow Making Good Impression

|

"Two farm implement manufacturers have expressed an interest in producing it commercially," Dickson told FARM SHOW. He also has hopes of getting the new tillage implement approved for cost sharing payments as a conservation seeding practice. "It looks much better than many practices already approved," he says.

The new invention "waffles" the soil surface with geometric patterns designed to increase infiltration and reduce runoff and evaporation, thereby routing more rainwater to plant roots.

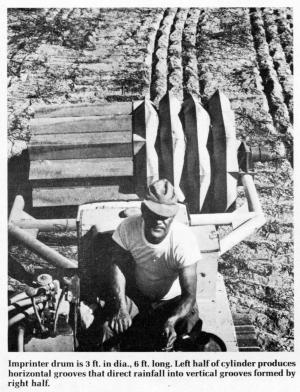

The imprinter drum is about 3 ft. in dia. and 6 ft. long. Half of the drum has a corrugated face that imprints grooves into the soil that; in turn, direct rainfall into grooves made by the other half of the imprinter. (See photo) Imprints can be made up into a number of shapes, all of which form a geometric pattern that has V-shaped bottoms to catch and retain the seed and soil moisture.

The drum itself is hollow and made from 112 in. steel plate. It can be filled with water to increase weight to about 3 tons. In addition, 2 more tons of steel bars can be mounted on the frame. "The machine can be used on heavy soils, can help chew up vegetation to provide a mulch, and it can press rocks into the soil if necessary," Dickson explains. "Since the imprinter rolls like a wheel and does not lift or disturb the soil like plows or disks, a large hp. tractor is not needed. We have gotten satisfactory results with a 30 hp. tractor."

The imprinter has only one moving part in the form of a compound roller and central axle which turn together as a rigid assembly during operation.

The roller itself is actually two separate capsules, each about 3 ft. wide and 3 ft. in dia. They are linked rigidly together by an axle pulling clamp on the axle, and by a sheet of rubber between the drums to keep them from turning independently of each other. Thus far, we have developed 10 interchangeable imprint capsules or rollers, thereby giving us 45 different possible combinations for the compound roller."

The points of the imprinter face are

made of 6 in. angle iron and hardfaced so that they're self sharpening. A seeder can be mounted on the imprinter, or seeds can be flown on by airplane after the soil is imprinted.

Due to the V-shaped configuration of the furrows, seed falls to the bottom of the furrows in a precise pattern. Seeding is as accurate as if it had been done by a drill.

Normal rainfall will do a good job of burying the seed but small discs or wheels can also be mounted on the U-shaped bar, or a chain can be dragged to bury the seed.

The imprinter leaves virtually all of the above ground plant material on the soil surface where it can retard runoff, sealing and evaporation, and enhance the roughness and porosity which increases water infiltration.

The imprinter performs a number of functions. It can crush and press brush and small rocks and imbed these in the soil. It also speeds runoff from one area and induces infiltration in another, forms a vertical mulch and prepares a seedbed. Other functions include wind and water erosion control, surface compacting and surface digging.

The soil should be somewhat moist for best soil impression but it should not be so wet that the soil sticks to the imprinter.

"Compared to other minimum tillage implements, the imprinter would have a slightly higher initial cost, but lower operation and maintenance cost, and more versatility. Since it has only one moving part, and is made from thick steel plate, it is virtually indestructible," Dickson points. "The only maintenance required is to grease the axle bearings during use and to coat the imprinter points between use with fuel oil to prevent rusting. With axle modifications, it might even be possible to replace the rear wheels of the tractor with imprint capsules, thus making the imprinter self propelled."

Dickson notes that the experimental imprinter under test is being used to increase range land and forage production throughout the state of Arizona. "However, it may someday find its use in croplands either as a secondary tillage tool or the sole implement for preparing a seedbed," Dickson notes. "It could lead to increased and more stable yields of corn, soybeans, grain sorghum, and wheat in drylands. The imprinter could eliminate the need for fallow in some wheat growing areas of the Great Plains. It could also be useful in areas where double cropping is not now possible due to lack of moisture for the second crop."

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.