2004 - Volume #28, Issue #5, Page #09

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

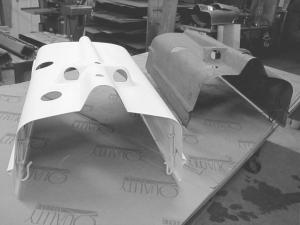

He Turns Tin Into "Gold"

|

|

"I was working in a sheet metal shop when a guy with a Massey Harris 101 Super came in and asked me to make a grill and louvered panels for it," recalls Greg Lillo. "Before I knew it, I had a year and half of work built up with no advertising. I only went to a couple of shows. Now I have parts all over the U.S. I even built a Hart Parr tool box for a guy in Germany."

The toughest thing about turning tin into "gold" is pricing, says Lillo. While some requests are very straightforward, for first-time parts he often has to make his own dies. Once they are made, he can use them for future orders for the same piece. It's pricing the first piece that's tough.

"An order for Massey Harris grills and panels took four months just to make the dies and complete the order," recalls Lillo. "Some stuff, you have to make a dozen sets just to pay for the jigs and dies you need to make one."

Lillo has worked on 12 makes of tractors, 58 separate models and 126 different parts. He now has plasma cutters, welders for aluminum and stainless steel, and even a 10-ft. break.

"I haven't had a part yet that I couldn't make," he says. "There have been quite a few parts I haven't made any money on yet, though."

Lillo estimates that in the 2 1/2 years he has been doing tractor parts full time, he has built up an inventory of $50,000 in dies and another $1,000 in reference books.

His die inventory is opening up new doors for his business. He is trying to do more quantities of parts - such as hoods - selling them in bulk to antique tractor supply companies.

A big key to the business is quality. "I keep a metal dumpster outside the shop," he explains. "If a part isn't perfect, it goes in the dumpster. I build it the way I would like to buy it."

The results often lead to more business. Lillo tells about one of his first Hart Parr customers who wanted to do his own fenders, but have Lillo do the hood. After he put on Lillo's hood, the fenders looked bad in comparison, so he had Lillo do them, too.

Currently, he is booked about 9 to 12 months out, but sometimes he gets multiple requests for the same part. Then he just does both. Recently that happened with a 2132 Twin City, predecessor to Minneapolis Moline. He was geared up to do one when he got a request for the same part from another customer. To do a part for the first time, he carefully measures the part to be reproduced. Once it is finished, he will try to find a similar tractor nearby and try it out.

"The nice thing is seeing a tractor at a show and seeing parts on it that I made," says Lillo.

Contact: FARM SHOW Followup, Greg Lillo, 56630 177th Lane, Good Thunder, Minn. 56037 (ph 507 278-3504; email: GREGGLILLO@aol.com).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.