1993 - Volume #17, Issue #2, Page #16

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Arkansas Farmer Builds Flame Weed Cultivator

|

|

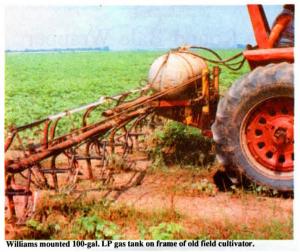

Williams mounted a 100-gal. LP gas tank on frame of an old field cultivator. He bought the burners from a Wisconsin company (Thermal Weed Control Systems, Inc., ph 715 743-4163) and used Arkansas Extension Service plans to mount a "water shield" above each burner. The "water shield" consists of a spray nozzle that wets down cotton stalks to protect them from the flames.

"It isn't pretty but it works great. I spent only about $1,200 to build it," says Williams. "I patterned it after the Afco flame cultivator that used to be sold by the Arkansas Foundry Association. Wet conditions in recent years had kept me from being able to spray morningglories early in the season. After morningglories wrap up around cot-ton plants, there's not much that can be done except to flame them.

"However, I couldn't fmd an 8-row flame cultivator on the market so I decided to build my own. It works great on morningglories because they're much more heat sensitive than cotton plants. It doesn't work as well on johnsongrass or redvines because they have woodier stems. However, it works well on any weed less than 2 1/2 in. tall. Cotton has to have a woody bark stem before it can withstand the flames. I make a second pass within three days to hit any weeds that aren't killed in the first pass.

"It's less expensive than spraying or hand hoeing. Last year I spent $9 to $10 per acre for each post-directed herbicide application and $12 per acre for hand hoeing. My cost for LP gas averages only $4.50 to $4.85 per acre under moderate to heavy weed pressure. I can operate the flame cultivator at2.5 to 4 mph under most conditions and cover 12 to 15 acres before I have to refill. I could switch to a 300-gal. tank to get more capacity. To start the flames, I turn on a valve from the tractor seat that ignites a pilot light on each burner. I turn another valve to pump water from a tractor-mounted tank to the "watershield" nozzles. Valves mounted in the tractor cab allow me to switch from 8 to 4 rows for spot control.

"I generally make a test run before I flame cultivate the entire field. I make one pass, then wait a half hour to an hour to see the results so I know whether I need to adjust the burner or pressure."

Proper height adjustment of burners is important for effective control and to re-duce injury to cotton stalks. Burners can be adjusted up or down, from side to side, or tilted at different angles with a wrench.

Williams received help from county agent Joe Vestal, Lewisville, Ark. (ph 501 921-4744), in designing his burner and water shield system. The water shield nozzle mounts about 21/2 in. above the burner. "It confines the heat to a localized area by wetting down the cotton plant," says Vestal. "The water reduces the flame temperature on the cotton canopy by 35% to greatly reduce crop injury."

Contact: FARM SHOW Followup, John T. Williams, Rt. 1, Box 100, Bradley, Ark. 71826 (ph 501894-3409).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.