Kernel Processors For Deere Forage Harvesters

✖  |

"More and more farmers are realizing the value of using a kernel processor to boost the nutritional value of feed," says Paul Smucker, Lancaster Silo Co., Lancaster, Pa. Last year FARM SHOW featured the company's silo blower equipped with a roller mill, as well as a kit for installing a roller mill on a pull-type forage harvester (Vol. 21, No. 5).

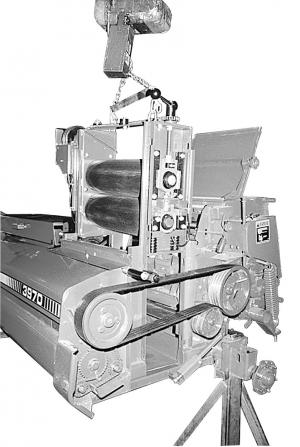

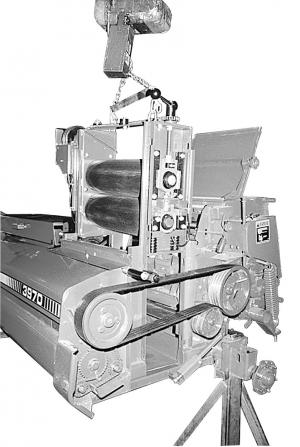

Now the company has introduced retrofit models for Deere 3950 and 3970 pull-type forage harvesters. In addition, its kernel processors now are factory-installed by Deere into its 5000 Series self-propelled forage harvesters.

The heart of the retrofit kit is a belt-driven insert with two 9 by 24-in. machine-grooved rolls that turn at different speeds. Processed silage moves quickly through to the auger assembly of the harvester. By removing 8 bolts the insert can be easily removed and replaced with a haylage chute (included with the kit) for processing haylage. The conversion takes only about 30 minutes. List price for the retrofit kit is $11,500.

Contact: FARM SHOW Followup, Lancaster Silo Co., 2008 Horseshoe Road, Lancaster, Pa. 17601 (ph 717 299-3721; fax 3978).

Click here to download page story appeared in.

Click here to read entire issue

Kernel Processors For Deere Forage Harvesters HAY & FORAGE HARVESTING Accessories 22-4-17 "More and more farmers are realizing the value of using a kernel processor to boost the nutritional value of feed," says Paul Smucker, Lancaster Silo Co., Lancaster, Pa. Last year FARM SHOW featured the company's silo blower equipped with a roller mill, as well as a kit for installing a roller mill on a pull-type forage harvester (Vol. 21, No. 5).

Now the company has introduced retrofit models for Deere 3950 and 3970 pull-type forage harvesters. In addition, its kernel processors now are factory-installed by Deere into its 5000 Series self-propelled forage harvesters.

The heart of the retrofit kit is a belt-driven insert with two 9 by 24-in. machine-grooved rolls that turn at different speeds. Processed silage moves quickly through to the auger assembly of the harvester. By removing 8 bolts the insert can be easily removed and replaced with a haylage chute (included with the kit) for processing haylage. The conversion takes only about 30 minutes. List price for the retrofit kit is $11,500.

Contact: FARM SHOW Followup, Lancaster Silo Co., 2008 Horseshoe Road, Lancaster, Pa. 17601 (ph 717 299-3721; fax 3978).

To read the rest of this story, download this issue below or click

here to register with your account number.