1993 - Volume #17, Issue #3, Page #04

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Hooded HIllside Sprayer

|

Beckley used 2 1/2-in. sq. steel tubing to build the sprayer frame in hinged 12-ft. sections. He used 3-in. wide angle iron to build the skids (except for the two outside skids which are made out of 2-in. dia. pipe) which are hinged on the bottom so they can flex up and down or forward and backward. The front and back end of each skid is bent up at an angle to ride over bumpy ground (he cut notches in the angle iron to bend it, then welded the notches closed). He uses a 250 hp Caterpillar D6C to pull the big sprayer.

"The skids smooth out the bumps which greatly reduces bouncing and damage to the sprayer. It rides as smooth as silk," says Beckley, who grows winter wheat on 5,400 acres of steep land. "We had been using a conventional wheeled sprayer. However, it tended to slide downhill and the wheels bounced up to 4 ft. off the ground whenever they hit a bump, especially on sharp turns around contours. It caused the boom to break into pieces. The skids ride with the sharp edges of the angle iron down which keeps sprayer from sliding downhill. They make a line through the field no wider than my finger for minimal crop damage.

"However, skids don't work well in soft ground because they sink in too far. When-ever we have to spray in soft ground we replace the skids with wheels.

"We cover the boom with a canvas hood that covers only the top and front side of the boom (photo shows canvas in back but that has since been changed). We mounted 1/4-in. plywood doors in front of boom and hooked a hydraulic cylinder up to each door. By activating cylinders we caf open the doors on-the-go to check the nozzles.

"The sprayer can't be folded up for trans-port. However, we can move it anywhere on our farm without folding it up."

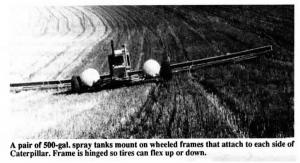

A pair of 500-gal. spray tanks mount on home-built wheeled frames that attach to each side of the Caterpillar. They're carried by tires salvaged from a 1960 Deere 95H combine. The frame is hinged so that the tires can flex up or down. He cut off the combine axle and mounted a sprocket and 3: 1 ratio planetary gearbox inside one of the wheel hubs. He then mounted a ground-driven spray pump on a stub axle that comes out of the gearbox. "The gearbox turns three times as fast as the combine tires and chain-drives the pump at the proper speed," says Beckley. "If the tanks were mounted on the sprayer their weight would cause it to slide down hill."

Contact FARM SHOW Followup, Carl Beckley, Box 728, Benge, Wash. 99105 (ph 509 887-2415).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.