1989 - Volume #13, Issue #5, Page #29

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Junked Baler Makes Great Windrow Inverter

|

|

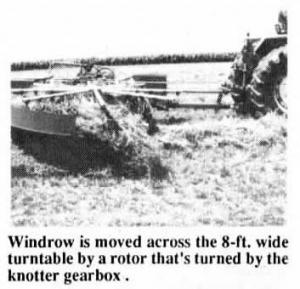

The hay windrow is moved across the 8-ft. wide turntable by a rotor that's turned by the gearbox that used to run the baler's knotter. A series of chains and sprockets was used to gear the rotor to the right speed.

"It's a low cost alternative to a commercial windrow inverter and does a better job than a rake," says Pangrac, who built the rig for about $1,000. "This windrow inverter helps me bale higher-quality hay, cutting 1 to 1 1/2 days off drying time. My self-propelled swather lays windrows that are too narrow for heavy alfalfa to dry adequately. I don't like to rake alfalfa because it can cause roping, which restricts air movement through the hay. Also, rakes sometimes roll the hay too far over, putting wet hay back next to the ground again. My inverter gently lays hay upside down on dry ground. It doesn't rope hay and allows good air circulation throughout the windrow."

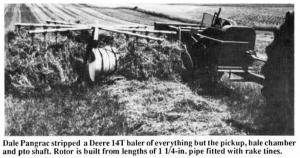

Pangrac stripped all components from the baler frame except for the pickup, bale chamber and pto shaft. A local blacksmith built the turntable from sheet metal and the rotor from lengths of 1 1/4-in. pipe fitted with rake tines. Pangrac welded the pipes to a heavy metal plate at the center of the turntable. He bolted the metal plate to a vertical shaft driven by the knotter gearbox below the turntable. Pangrac welded the turntable to the baler's frame just behind the pickup..A hydraulic orbit motor drives the rotor. A 10-in. high metal backstop welded to the turntable keeps hay from falling off.

Pangrac says the biggest challenge was making the rotor turn at just the right speed which he accomplished by aligning a combination of six chains and sprockets on the outside of the bale chamber. "The rotor has to turn very slow compared to the baler's ground speed and pickup speed. If the rotor goes around too fast, hay wraps around it. The rotor has to go just slow enough to drop hay gently off the end of the turntable, leaving the windrow the same width while tedding the hay slightly for faster drying."

Contact: FARM SHOW Followup, Dale Pangrac, Rt. 2, Box 77, Lewiston, Minn. 55952 (ph 507 523-2048).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.