Mower Fitted With Sickle Section Blades

"We've mowed our 3-acre farm yard with it for 10 years with no problems. Does a beautiful job and it's inexpensive to replace blades when needed," says Ken Craven, Byars, Okla., about his home-built tractor-pulled mower deck that uses a unique cutting blade fitted with sickle sections on either end.

"At the time we built it, it cost us $1,200 less than a similar size commercial mower deck made out of aluminum or sheet metal. We feel ours is much better because it's made out of 3/16-in. plate steel and is fitted with heavy caster wheels mounted on brackets that make it easy to adjust height.

"We used a belt pulley gear box from an 8N Ford tractor as a right angle gearbox and used bearing hubs from an old Wheelhorse mower deck to mount the three blades. The 4 pulleys for the gearbox and hubs came off a junked combine and we got the drive belt from a New Holland 469 Haybine.

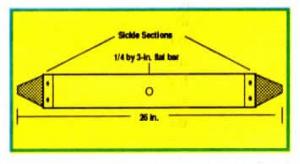

"Blades are 2 ft. long and made out of 3-in. wide, 1/4-in. thick flat bar steel with standard mower sickle sections riveted to each end. These inexpensive blades also work great on conventional mowers. A friend of ours used the idea on a Sears riding mower. We replace the sickle sections once a year unless we hit a rock or something.

"Other than sickle sections, we've only replaced one idler pulley and 2 belts in 10 years."

Contact: FARM SHOW Followup, Ken Craven, Rt. 1, Box 43, Byars, Okla. 74831 (ph 405 469-4326).

Click here to download page story appeared in.

Click here to read entire issue

Mower fitted with sickle section blades FARM HOME Lawn Mowers (31h,38) 17-3-2 "We've mowed our 3-acre farm yard with it for 10 years with no problems. Does a beautiful job and it's inexpensive to replace blades when needed," says Ken Craven, Byars, Okla., about his home-built tractor-pulled mower deck that uses a unique cutting blade fitted with sickle sections on either end.

"At the time we built it, it cost us $1,200 less than a similar size commercial mower deck made out of aluminum or sheet metal. We feel ours is much better because it's made out of 3/16-in. plate steel and is fitted with heavy caster wheels mounted on brackets that make it easy to adjust height.

"We used a belt pulley gear box from an 8N Ford tractor as a right angle gearbox and used bearing hubs from an old Wheelhorse mower deck to mount the three blades. The 4 pulleys for the gearbox and hubs came off a junked combine and we got the drive belt from a New Holland 469 Haybine.

"Blades are 2 ft. long and made out of 3-in. wide, 1/4-in. thick flat bar steel with standard mower sickle sections riveted to each end. These inexpensive blades also work great on conventional mowers. A friend of ours used the idea on a Sears riding mower. We replace the sickle sections once a year unless we hit a rock or something.

"Other than sickle sections, we've only replaced one idler pulley and 2 belts in 10 years."

Contact: FARM SHOW Followup, Ken Craven, Rt. 1, Box 43, Byars, Okla. 74831 (ph 405 469-4326).

To read the rest of this story, download this issue below or click

here to register with your account number.