1991 - Volume #15, Issue #1, Page #10

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

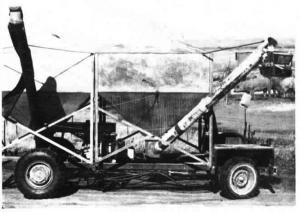

Self-Propelled Hydrostatic Drive Hog Feed Wagon

|

|

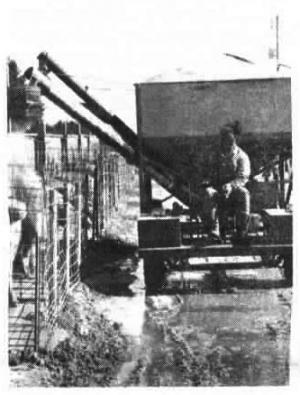

"The tank", as Rodocker calls it, is powered by a 16 hp Briggs & Stratton engine salvaged from a riding lawn mower. It's equipped with two tanks salvaged from an old grain vacuum rig that each hold 100 bu. of feed. Rodocker sits in front and uses a directional lever to steer the rig along a fenceline. A dump scale bolted to the output end of the front tank's unload auger lets him dump measured amounts of feed on-the-go over a fenceline onto the cement floor of each sow pen. An 8-ft. long canvas "sock" mounted on the end of the rear tank's auger is used to drop feed into feeders for small pigs. The rig travels at up to 4 mph.

"I built it after my kids went to college and I was left to feed alone," says Rodocker, who operates a 160-sow outdoor farrow-to-finish operation. "It does the work of a feed mixer truck, but is more versatile because it has two separate tanks. The front tank is set up for sow feed and contains a separate compartment that holds 300 lbs. of medicated feed. A 2-in. dia. auger, activated by an electric switch, slowly adds medicated feed to the sow feed as needed. I drive non-stop along the fenceline and feed the exact amount of feed needed by each sow. The dump scale lets me drop 3 to 12 lbs. of feed at a time by pulling a lever. Colored flags mounted on the pens show how much to feed. A green flag means the sow has farrowed and gets three dumps of feed. A red flag means she hasn't farrowed and gets only one dump of feed.

"To feed small pigs, I get off the ma-chine, stick the end of the sock into each pig feeder, and pull a spring-loaded cable that's hooked to an electric solenoid valve. When the feeder is almost full, I let go of the cable.

"I had been bucket feeding from a pickup, but it took too much time. I can feed 160 sows in about five minutes compared to 1 1/2 hours when I was bucket feeding and I had to grind a new load of feed twice a day. Each tank on my home-built feeder wagon holds two tons of feed so I can grind feed less often." The feed wagon has three levers. The hydraulic steering lever works like an airplane steering stick. Rodocker pushes it left to turn left and right to turn right. Another lever controls forwardand re-verse direction. The third lever controls the augers. A dual hydraulic pump runs off the engine with one pump powering and steering the rig and the other pump running a pair of hydraulic motors that power the augers on each tank. A foot pedal lets Rodocker speed up or slow down. To steer the rig he connected a hydraulic valve to a two-way hydraulic cylinder mounted on front axle's tie rod.

Rodocker built the rear end with the axle, wheels, and rear end from a 1976 Ford 3/4-ton pickup and the front end by salvaging an axle from a Chevrolet van. The 16-in. high rear tires are cleated. He built the chassis from 2 by 4-in. channel iron. The augers are off an old feed mixer truck and the seat is from the van. A 12-volt battery is used to start the engine. On the left side of the wagon Rodocker mounted a fold-up catwalk. The rig is equipped with headlights, brake lights, and a light that shines on the augers for feeding after dark.

Contact: FARM SHOW Followup, Wayne Rodocker, Box 1, Halsey, Neb. 69142 (ph 308 834-3341).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.