Big slices of prairie sod provided solid building blocks for the new machinery shop on Leroy Staffanson's Sidney, Mont., farm. He built 9-ft. high, 5-ft. thick walls using sod-cutting and handling equipment he built himself.

The 25 by 50-ft. "sod hut" building is built into the side of a hill. Staffanson poured a 4-in. thick slab of concrete across the top of the thick walls to form a foundation for a 5-ft. tall wood-frame "upper story" that covers the top of the building.

"I got the idea when I saw a sod house in South Dakota that's still standing. I figured we could use sod here, too," Staffanson told FARM SHOW.

The key to success is erecting a sod structure in the sod itself. It should have a strong root structure so it'll hold together while it's worked into place. Staffanson cut sod from the lower end of a pasture that was covered with "slough grass" that he says hangs together well. He built a rear-mounted, single shanked sod "harvester" with a horizontal cutter bar that runs underground parallel to the surface. A pair of cutting discs on either side cuts the sod loose in two even strips about 6 in. thick and 1 1/2 in. wide.

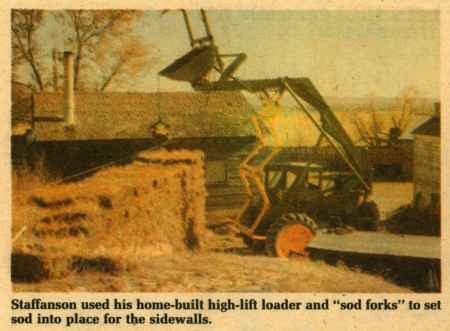

Staffanson built a pair of forks that fasten to a scissor-shaped frame suspended by chain from a tractor loader to load sod onto trucks. His special-built high-lift tractor loader came in handy for moving sod into place on building walls (his high-lift loader was featured in FARM SHOW Vol. 8, No. 3 issue).

Constructing walls was simply a matter of transferring sod from the truck. Walls are 5 ft. thick but could be easily varied. Staffanson let the walls settle for several months once constructed and then coated the insides with white plaster. He plans to coat the outside walls, too, so that it will be impossible to tell that the building was constructed with sod. He also plans to put heating pipe into the cement floor and heat the building with a coal-fired boiler. He built a big 17-ft. wide bi-fold door for the building that's counter-balanced with sections of cut-up grader blade and powered by a 1/6 hp motor channelled through a 50 to 1 reduction gear. The building has 14-ft. clearance from floor to rafters and another 6 ft. to the peak. The upper portion of the building is sided with corrugated metal. The entire project took Staffanson about 2 years to complete, working in his spare time between farm work and other projects.