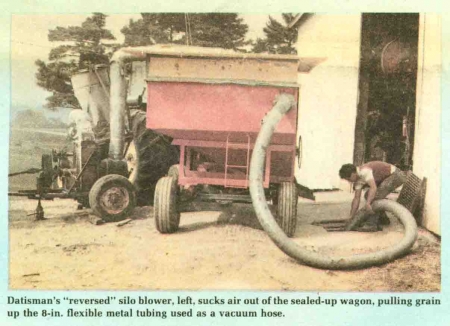

One of the best farm shop ideas we've seen lately is this low-cost grain vacuum that Iowa farmer Roger Datisman, of Sherrill, designed and built, using an old silage blower and his 200 bu. grain wagon.

It's unbelievably simple. You can build it yourself if you've got an old unused silage blower sitting out behind the barn.

Here's how Datisman did it.

First, he converted his 200 bu. grain wagon into a giant vacuum chamber by installing a layer of perforated flooring across the top and built a 1-ft. high plywood extension above the flooring. He then sealed the wagon shut with a sheet of plywood across the top, cutting an 8-in. dia. hole in one end of the plywood sheet and another the same size in the side of the wagon below the perforated floor.

"I built the vacuum itself out of an old Allis Chalmers silo blower with a barrel mounted in the back of it -- where the silage intake opening was located -- to act as a suction chamber. An 8-in. metal duct runs from the barrel up to the hole in the top of the wagon. A length of flexible tubing with a large metal 'nozzle' is attached to the hole in the side of the wagon. When the blower is turned on, suction is created, pulling grain up the flexible tube and into the wagon below the perforated floor. Once corn is in the wagon, the floor keeps it from going up into the vacuum tube at the top of the wagon," explains Datisman.

He tripled the speed of the 540 rpm pto-driven blower/vacuum with a large drive pulley. The blower is mounted on its own trailer and powered by a separate tractor. Datisman says he plans to buy a better quality blower and mount it on the front of the wagon so the vacuum will be self-contained and require only one tractor to transport.

The unique grain vacuum sucks up 250 bu. of corn an hour. Datisman figures that, by sealing up the wagon and tubing, and obtaining a stronger blower, he should be able to easily boost capacity to more than 500 bu. per hour. To transfer grain from one bin to another, the operator simply fills the wagon, turns off the vacuum, dumps the grain into a transfer auger, then fills the wagon again.

Datisman, who has experimented with various lengths of flexible tubing on the vacuum, says the suction is so strong he can use up to 50 ft. of tubing if needed. He doesn't shut the system off until the wagon is full and the tube starts filling up. He notes that it's important to make air holes in the nozzle so it can be placed directly into the grain without "choking".

"It works much better than sweep augers for clean out and is handy for getting into corners. It's especially good for grain stored in hard to get at spots, such as the grain I store in my old dairy barn. And, the vacuum can be converted back to a conventional grain hauling wagon in 10 min. or less," he notes.