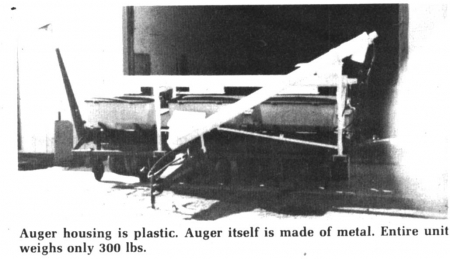

Out of a farmer's workshop comes this plastic auger for easy loading of granular fertilizers into fertilizer hoppers on planters.

The versatile new auger mounts permanently on the planter and weighs only 300 lbs. It eliminates the need for specially equipped fertilizer wagons and trucks. Invented by Richard Fiechter, of Bluffton, Ind., it's being marketed and Manufactured by Hively Manufacturing, Roann, Ind.

"Some of the current planter models on the market have loading augers but they are often inflexible. You have to move the planter to get into loading position. With our model, you just maneuver the loader arm," explains Lawrence Hively, president.

Although the entire auger housing is plastic, the auger flighting is metal. A prototype has been in use for several years, without extreme signs of wear. Plastic makes the auger light-weight and more resistant to corrosion from the fertilizer.

Hydraulic motors driving both the loading auger and the distribution auger across the hoppers are powered through a single valve off the tractor. Capacity is about 1,500 lbs. of fertilizer in four minutes.

The auger has so far been adapted to fit International's 800 planter, 6 and 8-row; the Allis Chalmers 330, 6 and 8 row; and the Deere 7000, 6 and 8 row. Units may adapt to other planters with slight alterations if the planter markers are moved behind the fertilizer boxes to allow the auger to swing around without interference.