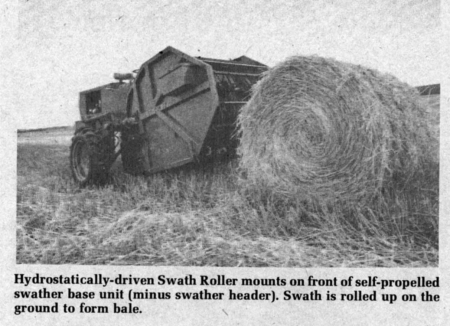

Farmers who've seen it are excited about a first-of-its-kind big round baler that's designed to mount right on the front of your self-propelled swather.

According to the machine's designer and manufacturer, John Shokopolis, of Nisku, Alberta, the new-style baler "not only frees a tractor for other work but costs less than conventional big round balers and does a better job.

"It's a great advantage to bale with the same machine that makes the windrow. Maneuverability is excellent," explains Shokopolis. "Also, you're right on top of the baler so you never have to look back, and you never drive over the hay to damage it."

The all-hydraulic "Swath Roller", as it's called, is completely different from other balers in fundamental design. Rather than using a front hay pickup and then suspending the bale off the ground, the new Swath Roller baler uses a rear pickup and "snowballs" the bale -- actually rolling it along the ground, forming it into a tight roll at ground speed rather than any given rpm. Shokopolis says this feature lessens handling, thereby minimizing leaf loss and shattering. It also makes it possible to bale cornstalks and other material as easily as it handles hay. "This is because the baler wraps material around the bale rather than trying to lift it up and over," the manufacturer explains.

The baler is designed to mount with just 4 bolts on Versatile's model 400 or new 4400 hydrostatic swathers. Versatile supplies some 67% of the swather market in Canada so initial production models have been designed to fit them. But the company says they can fit most any brand self-propelled hydraulic swather on the market by designing new mounting brackets. They are also considering developing a power unit designed specifically for self-propelling the Swath Roller. Shokopolis says, "the complete self-propelled unit would cost only a couple thousand more than the best conventional round balers currently on the market."

It takes about 10 min. to mount the baler on your swather, once the swather table has been removed. Quick couplers tie the swather directly into the self-propelled unit's hydraulics.

Key operating features include: Quick start-up; automatic tying -- when the bale reaches full size, tying discs come in contact with the bale and start wrapping the twine; fast unloading -- just drive off the swath several feet, raise the baler hydraulically and watch the tied bale roll out; and no-plugging. If a foreign object should happen to jam the machine, just lift off the baler and remove the object.

The 2,800-lb. baler puts out a 5-ft. long bale measuring up to 5 ft. in dia. Compression springs adjust for density control, but the company doesn't recommend forming more than 1,000 lb. bales with the current model.

Versatile has worked with Shokopolis on design

and is considering selling the unit mounted on their swather power base.