You've never seen a tillage tool quite like the revolutionary "underground plow" introduced by Lee Blacksmith, Rochelle, Ill.

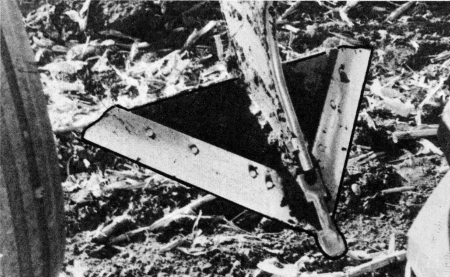

Designed primarily for fall tillage, it incorporates plowing, subsoiling, ripping, chiseling and disking. Large diamond-shaped shovels (30 in. wide) welded onto the ends of heavy rippers operate 12 in. underground to "lift" the soil.

"Its action differs from conventional subsoiling or ripping in that the huge shovels lift the soil for improved aeration and moisture penetration," explains John Dougherty, sales manager. "It goes through heavy trash, leaves no ridges or untitled gaps, and you end up with a trashy surface to stop snow and wind erosion. It can also be equipped to knife in anhydrous ammonia."

Ten machines currently in production will be shown at most major shows and fairs during 1977. Regular assembly line production and marketing will be launched well ahead of the '77 fall tillage season, according to Dougherty. "Farmers who field tested it for us last fall were well pleased with its performance," he told FARM SHOW.

The new tillage tool will be offered in 3 and 5 bottom models. The 5 bottom unit, with slightly over 2 in. spacing between shovels, has a working width of 160 in., and requires a 150 hp or larger tractor. It's comparable in capacity to a moldboard plow with ten 16-in. bottoms but requires slightly less horsepower. "We recommend a tractor of 150 hp or larger for the 5 bottoms, and 100 hp or larger for the 3 bottom unit," says Dougherty. On soybean ground, the new-style tillage tool can move right in without any prior tillage. On heavy corn stalks, it's recommended that the stalks first be disked. It's expected that fields tilled with the new machine in the fall will only require a once-over disking in the spring prior to planting.