Where To Buy Custom-Cut Gears

Lyle Mack loves gear making so much he'll even help you make your own. The young machinist set up LM Gear and Machine on his family's farm to make gears, sprockets, and splined shafts.

"I got started a while back while building my own tractor, including the gears and shafts,? explains Mack. "I got so busy making the tooling for gears that I never finished the tractor."

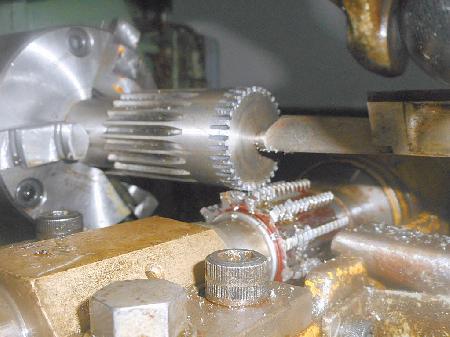

What he has done is build a business of his own. He can make a wide range of spur, helical, worms and worm gears, rack and pinion systems, and bevel gears of all sizes. He can work in any material in sizes from 1 to 15-in. diameter. He works in metric, standard and non-standard scales.

Mack has also built up a nationwide network of contacts and resources in custom machining.

"I'm ready to try anything, and I won't laugh at any idea," he says. "I like to work with do-it-yourselfers, people with an idea, but who don't know what size gears are needed based on horsepower and material, I can help them. If I can't, I know a lot of small shops I can direct them to."

If readers want to make their own gears, Mack is happy to help. He refers wannabe gear makers to "Gear Design Simplified" by Franklin D. Jones and Henry Ryffel.

"Another recommendation is "Gears and Gear Cutting" by Ivan Law," says Mack. "There are tons of resources on the internet, but those two cater to people getting started."

He notes that lots of machine shops will charge a lot for calculations and won?t work with crude drawings. "If you can come up with your own calculations, you can avoid that," says Mack. "When people need a specific gear or spline they can spend a lot of time trying to find one. It's often easier to make it yourself. It's not as hard as people think."

Mack will not only help with the math needed, he'll help find the lowest cost way to fix the problem of a busted gear or splined shaft. He understands that if a specialty gear breaks on an older machine, a replacement may not be available.

"If a person wants to get a machine going again, we'll figure out a way," he says.

Part of being able to do the job is having the right equipment. Mack is still "gearing up" with more expensive equipment, like a special mill to cut spiral, bevel gears. In the meantime, he is making the chucks and tooling he needs to get jobs done and has cut worm gears and bevel gears on his milling machine.

"A lot of shops will rent tooling for specialty internal splining," notes Mack. I've made internal splines and can produce internal gears and special shapes. I also have sources for off-the-shelf gears of most any design."

Prices vary with the job, from a minimum of $50 for the simplest gear work on up to several hundred for milling jobs. He describes his business goal as doing precise work at a farmer's price.

"If a farmer doesn't want to spend $700 on a single gear, I'll try to mill it for him," says Mack. "It may not be quite as precise, but it will get him up and running and should last for quite a few years."

If a part is needed, he suggests sending the damaged piece. However, he can work from basic drawings or even a crude sketch to replicate the part.

"I love helping people restore older equipment or make a prototype of something new," he says. "I'll consider most anything from little gears on older equipment to gears for pedal cars."

Mack is even willing to consult with people wanting to start their own shops like he has done. It is his way of paying back for the help and advice he has received.