"I've figured out how to rebuild old cultivator shovels for just a fraction of the cost of new ones," says Kirk Deardorff, Hale, Mo.

"I buy 1 1/2-in. wide, 1/4-in. thick flat iron by the foot for pretty cheap. That's about how much iron it takes to rebuild a worn-out shovel to like-new condition," says Deardorff.

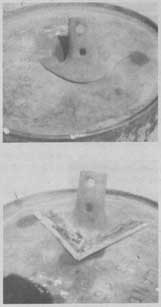

"Most cultivators have a 35 degree wing angle and an 8 degree up slope. Take two pieces of flat iron and cut off the ends at a 35 degree angle, the same length as the sides of the original shovels when new. Then weld two of the ends together, propping up the back edges to get an 8 degree slope.

"The next step is to clamp the worn shovel in position on top of the new wings and weld them together at the point. Heat the old shovel and hammer it down for a flush fit to the new wings. Then finish welding all along both edges and use a hand-held grinder to put a sharpened edge on the new wings.

"One problem is that the new mild steel wings will wear away quickly unless temper hardened. Here's how you can harden them:

"Immediately after welding and grinding, the wings and the sharpened edges will be very hot. Quickly immerse the entire shovel in water for 3 sec., remove for 3 sec., and then immerse again for 3 more sec. Then very lightly touch up the sharpened edges with a grinder to remove the burnt purple color."