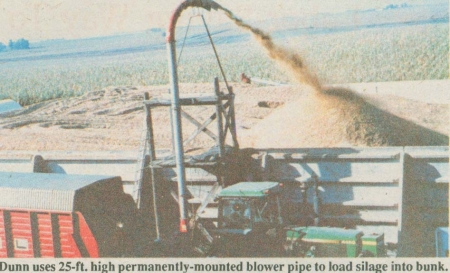

"It eliminates

the possibility of tractors and wagons getting stuck in silage, and allows us

to build a bunker silo that takes up less space," says Leo Dunn, Clemons,

Iowa, who uses a forage blower and a permanently-mounted 25-ft. high blower

pipe to fill his bunker silo.

Dunn chains the pipe to a platform that's bolted to the side of the 32-ft. wide by 120-ft. long by 14-ft. high bunker silo, which is closed on one end. He uses a Deere 4630 tractor equipped with a front-mounted blade to level the piles created by the blower.

"Other farmers in my area unload silage on-the-go from a wagon into a bunker silo that's open on both ends," says Dunn, who feeds 1,100 beef cattle. "The tractor and wagon can get stuck if the silage isn't packed down well enough. We can unload a wagon load of silage into the blower in 5 min. and there's no chance of getting stuck. Using the blower also allows us to close up one end of the bunker silo and build a shorter but taller silo that takes up less space."

Once the silo is filled, the silage pile at one open end is too steep to drive down with the 4630 tractor. Dunn attaches one end of a long cable to the 4630 and the other end to a tractor outside the silo. He then lets the cable out slowly to allow the tractor to roll backward down off the silo.

Dunn has two 20 by 80-ft. vertical silos that are located 100 ft. away from the bunker silo. When the vertical silos empty out, he refills them from the bunker silo with a 100-ft. long, 16-in. wide conveyor powered by a 10 hp electric motor.

Dunn had a

Humboldt, Iowa fertilizer equipment manufacturer bolt two 50-ft. long conveyors

together. He equipped the double conveyor with an old hammermill axle. He

mounted the motor on the bunk feeder end of the conveyor which is 3 ft. off the

ground. The other end of the conveyor is at ground level. Dunn uses a tractor

and front-end loader to load silage into a wagon which meters it onto the

conveyor belt.