You'll like the price tag on the just-introduced new spin-on method of wrapping big round bales in plastic.

Developed by the Bale-Bonnett Co., of Bloomsdale, Mo., it provides all-weather protection with cling-type plastic (it resembles Saran-Wrap). "It costs about one-third the cost of plastic sleeves or machine-wrap systems already on the market," notes Alan Schaefer, president of Bale-Bonnett and inventor-manufacturer of the new bale-wrapping system.

The "business end" of his new-style wrapper is a pointed spear (60 in. long and 2 1/2 in. in dia.) which is powered by a hydraulic motor and has a spiral-shaped rod welded to its outer surface which turns the pointed spear into a giant screw. "It rotates and screws its way into the bale in a straight line and doesn't veer off the to side, as often happens with plain pointed spears," notes Schaefer. "This spiraling on the spear, along with metal fingers welded to the spinner plate, allow the spinner-spear assembly to turn the bale as it's being wrapped with a hand-held roll of cling-stretch plastic."

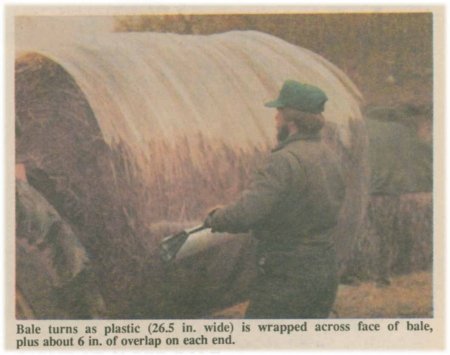

The 100 ga. stretch plastic (white over black with the white side out) comes in rolls 26 1/2 in. wide. "You start on one side with about 6 in. of overlap, then let the plastic wrap across to the other side as the bale turns," according to Schaefer. "It only takes about 15 or 20 seconds to wrap a bale. The beauty of this system is that you can let the plastic overlap about 6 in. on each end. This overlap, which self-stretches tight against the bale ends, keeps water from seeping in along the bottom, as generally happens when you cover just the face of the bale with plastic."

"The special cling-stretch plastic sticks to itself and doesn't have to be tied or glued to keep it from unwrapping in the wind, or when bales are handled and moved. Also, the plastic is durable and not easily punctured by hay stems. Two people are required to do the wrapping -- one on the tractor and one on the ground to handle the plastic," notes Schaefer.

He adds that "one size fits all" with his new bale-wrapping machine and its method of hand-applying 26 1/2-in. wide plastic to any and all big round bales, regardless of size or shape.

The spear-spinner assembly, complete with hydraulic motor can be used to transport, and to unroll and feed bales during the off season.

"We're getting a lot of interest from managers of co-ops who are thinking about buying a machine and renting it out to area farmers and ranchers," Schaefer told FARM SHOW.