"I've sold 160 sets of these new cut-off plow bottoms within 10 to 15 miles of my home and I've never had a set returned yet," says Jim Frambach, farmer-inventor of a new cut-off moldboard plow that busts up soil as it turns it, eliminating soil "slabs" and leaving 30 to 50% of residue on the surface.

Frambach says he chisel-plowed fields on his farm near Emmetsburg, Iowa for 15 years before he decided there had to be a better way. "Chisel plows leave grooves that can cause erosion and they often don't break up the ground enough, particularly in wetter soil," he notes.

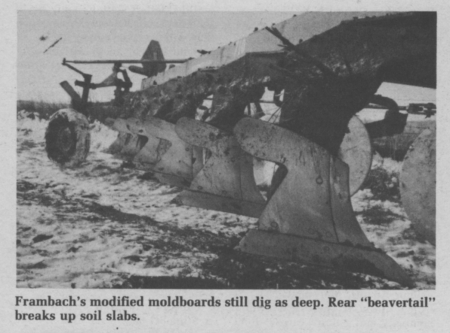

Frambach cut away the rear-end of the moldboard except for a rounded "beavertail" wing at the top. The plow's cutting edge, or "lay", remains the same width. When the plow starts to roll over a slab of soil it breaks up and crumbles together as it goes over the beavertail, leaving a nearly level soil surface with soil and residue mixed together.

Frambach made his first prototype models by cutting the moldboards with a torch. The plow bottoms are now being manufactured by Wiese Corp. in Perry, Iowa. He stresses that installation of the cut-off bottoms requires no modification of the plow. They simply bolt in place of the regular bottoms.

"You can cut down your own moldboards and try the idea yourself, but we're selling the bottoms for much less than the cost of conventional moldboards so we think it makes more sense to buy a set of these and keep your old moldboards in case you ever want to convert back," says Frambach.

Frambach says the cut-off bottoms pull much easier than conventional bottoms and stay in the ground better because the lifting action of the soil-turning moldboard is gone. "It leaves anywhere from 30 to 50% of the residue on the surface. If you want it blacker, you lightly disk the field before plowing."

Cut-off bottoms are available to fit most plows, including Deere, White, Case-IH, and others.