Skid Steer Loader Built From 75 Honda

Ontario welder and machine shop instructor Bill Fair of Paisley didn't want to spend the money for a new skid steer loader, so he built his own mini loader from a 1975 Honda Civic front-wheel drive car and other miscellaneous junk parts.

Fair uses the mini loader on his own farm as well as in a high school class he teaches on farm equipment repair.

"It turns in a 16-ft. radius and works much like a skid steer loader, but it cost only $1,500 to build," says Fair. "It works great for loading stacks of six small square bales at a time in the field onto wagons. I also use it to clean my barn, scrape snow, and pull empty wagons. The Honda engine is very fuel efficient. I mounted a 2-gal. plastic gas canon back, and those two gal. last a full day.

"I paid $100 for the car and spent a year building the loader. A new skid steer loader would cost about $10,000 and would be too slow to retrieve bales in the field. The engine is geared down at a 3:1 ratio so I can go real slow in first gear for field work or up to 30 mph on the high-way. The 1,250 cu. in., 4-cylinder gas engine has plenty of power. The only problem is I have to be careful I don't dig the front snow tires into the ground and twist an axle.

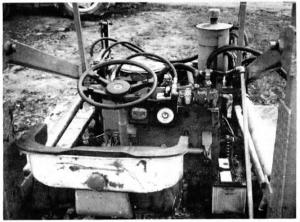

"I used every part I could from the car, including the tires, axles, steering wheel, rack and pinion steering, steering box, gearshift, clutch and gas pedals, rear wheel brakes, and part of the dash. I even converted the car's side marker lights to flashing safety lights that are mounted on the roof. I also mounted a radio and speaker under the roof. The seat is from an old tractor. I could pull the engine out by removing four bolts and replace it with the engine from my 1980 Honda. It would take only two hours to change engines."

Fair built a steel frame to mount the engine and hydraulic pump (salvaged from an old New Holland swather) that operates the loader. The pump is belt-driven by the engine. He made a firewall to mount the voltage regulator, clutch and gas pedals, and dash. He used 2 by 4-in. sq. steel tubing to make the loader arms and made the bale fork as well as three different buckets (the one shown measures 5 ft. wide, 14 in. deep, and 12 in. high). "The small size of the bucket and a 100 lb. weight mounted at the rear of the loader keeps it from tipping," notes Fair. "I use two small power steering cylinders off an old Case combine to dump the bucket. I pull two pins to remove the bucket and two more pins to remove the bucket's dump cylinders. The hydraulic control levers were borrowed from an old Ford tractor."

Fair geared down the engine byadding a set of sprockets between the transmission and axles, which are both chain-driven. He raised the engine and trans-mission to make room for the drive system and lowered both axles by removing the pillow block bearings they were mounted on.

Contact: FARM SHOW Followup, W.T. Fair, Rt. 3, Paisley, Ontario Canada N0G 2N0 (ph 519 353-5940).

Click here to download page story appeared in.

Click here to read entire issue

Skid Steer loader built from 75 Honda FARM HOME Cars 15-6-8 Ontario welder and machine shop instructor Bill Fair of Paisley didn't want to spend the money for a new skid steer loader, so he built his own mini loader from a 1975 Honda Civic front-wheel drive car and other miscellaneous junk parts.

Fair uses the mini loader on his own farm as well as in a high school class he teaches on farm equipment repair.

"It turns in a 16-ft. radius and works much like a skid steer loader, but it cost only $1,500 to build," says Fair. "It works great for loading stacks of six small square bales at a time in the field onto wagons. I also use it to clean my barn, scrape snow, and pull empty wagons. The Honda engine is very fuel efficient. I mounted a 2-gal. plastic gas canon back, and those two gal. last a full day.

"I paid $100 for the car and spent a year building the loader. A new skid steer loader would cost about $10,000 and would be too slow to retrieve bales in the field. The engine is geared down at a 3:1 ratio so I can go real slow in first gear for field work or up to 30 mph on the high-way. The 1,250 cu. in., 4-cylinder gas engine has plenty of power. The only problem is I have to be careful I don't dig the front snow tires into the ground and twist an axle.

"I used every part I could from the car, including the tires, axles, steering wheel, rack and pinion steering, steering box, gearshift, clutch and gas pedals, rear wheel brakes, and part of the dash. I even converted the car's side marker lights to flashing safety lights that are mounted on the roof. I also mounted a radio and speaker under the roof. The seat is from an old tractor. I could pull the engine out by removing four bolts and replace it with the engine from my 1980 Honda. It would take only two hours to change engines."

Fair built a steel frame to mount the engine and hydraulic pump (salvaged from an old New Holland swather) that operates the loader. The pump is belt-driven by the engine. He made a firewall to mount the voltage regulator, clutch and gas pedals, and dash. He used 2 by 4-in. sq. steel tubing to make the loader arms and made the bale fork as well as three different buckets (the one shown measures 5 ft. wide, 14 in. deep, and 12 in. high). "The small size of the bucket and a 100 lb. weight mounted at the rear of the loader keeps it from tipping," notes Fair. "I use two small power steering cylinders off an old Case combine to dump the bucket. I pull two pins to remove the bucket and two more pins to remove the bucket's dump cylinders. The hydraulic control levers were borrowed from an old Ford tractor."

Fair geared down the engine byadding a set of sprockets between the transmission and axles, which are both chain-driven. He raised the engine and trans-mission to make room for the drive system and lowered both axles by removing the pillow block bearings they were mounted on.

Contact: FARM SHOW Followup, W.T. Fair, Rt. 3, Paisley, Ontario Canada NOG 2N0 (ph 519 353-5940).

To read the rest of this story, download this issue below or click

here to register with your account number.