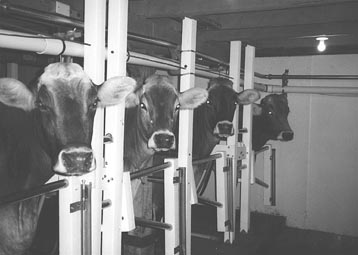

You won't find an easier to maintain milking parlor than the one built by Gary Lisowe, Gillett, Wis., who used "plastic lumber" and stainless steel pipe to put together a 4-unit, walk-through milking parlor. "It was fairly economical to build, but the biggest advantage is that the materials I used will never rot or rust and they clean up like new," says Lisowe, who milks a herd of registered Brown Swiss cows. The stalls were set up on top of a 10-in. high concrete platform. Lisowe bought the stainless steel pipe at an auction held by a farmer who had quit milking cows. He bought the plastic lumber -- which consists of white 4-in. sq. posts -- from a company in Green Bay. The pipe was used to form the sides of the stalls. The posts were used on the corners. They mount on stainless steel plates that bolt to the concrete floor. The pipes were also used to build "catch and release" gates at the front of each stall. Each gate is manually opened or closed by pulling on a lever attached to a cable and pulley system. Cows stand "on their honor" during milking without any restraint. Once milking is complete, the operator pulls the lever allowing the cows to step forward and exit the parlor. The operator sits on a 14-in. long, 6-in. wide "swinging stool" also made from plastic lumber. The stool is free to swivel at the end of a 1 1/4-in. dia. galvanized steel pipe. The pipe itself pivots on brackets attached to a vertical steel post. "I set up this parlor four years ago and have used it to milk 30 cows twice a day, which comes out to about 75,000 milkings. I've only had to make minor adjustments and repairs," says Lisowe. "One person can milk up to 30 cows per hour with four milking units, even though they're not equipped with automatic take-offs. The plastic lumber cost about two and a half times as much as wood, but it's worth it because it never rots and never has to be repainted. To attach the pipes to the posts I ran a 3/8-in. dia. threaded steel rod through each pipe and recessed the end of each rod in the sides of the posts."

1-800-834-9665

Milking Parlor Made From Plastic Lumber

FARM SHOW Magazine » Milking Parlor Made From Plastic Lumber

Milking Parlor Made From Plastic Lumber