1989 - Volume #13, Issue #3, Page #06

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

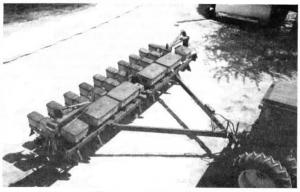

8 Row 38 Inch Planter Converted To 10 Row 30 Inch Planter

|

"My old 8-row, 38-in. planter, which I had always used to plant 36-in. rows, was seven years old and ready to be traded. I wanted to switch to 30-in. rows, but I didn't want to buy a 12-row 30-in. planter because it costs about $6,000 more than an 8-row model. I couldn't justify that expense on my 900-acre farm. Also, if I had bought a 12-row planter, I would have had to trade in both of my 8-row cultivators and my 8-row rotary hoe.

"On the other hand, I didn't want to buy an 8-row 30-in. planter because it would have slowed planting down. An 8-row 30-in. planter loses two rows for every 1 1/2 rounds compared to an 8-row 38-in. planter. Since the main frame of an 8-row planter is basically the same one used on a 12-row planter, it's heavy and wide enough to carry ten 30-in. rows. So far it has worked out great."

Clement modified the planter for 30-in. rows by moving the eight row units closer together and adding two row units, one on each outside wing of the planter. To make room for all of the row units he had to reposition some of the carrying wheels as well as one of the planter's two transmissions, which he unbolted and slid over about 10 in. Each outside wing of the planter had originally consisted of two row units driven off the transmission by a 38-in. long hexagon drive shaft. To drive the additional row unit on each wing, Clement replaced the 38-in. long drive shaft with a 50-in. long shaft which operates all three row units.

Clement added two gangs to his cultivator and set all gangs on 30-in. rows. He traded his 4-row corn head in for a 6-row 30-in. corn head. "The key to combining 10-row planted corn with a 6-row corn head is to plant as straight as possible and stay within a couple of inches of the marker," says Clement, who notes that he didn't have to modify his 8-row rotary hoe at all for narrow rows.

The planter came factory equipped with four toolbar-mounted fertilizer boxes. There wasn't room to add a fifth full fertilizer box so Clement mounted half of a fertilizer box onto each end of the toolbar. He made each box by cutting one full box in half and "telescoping" the halves in-side each other.

Clement also rewired his Dickey-John population monitor to read off 10 rows instead of eight.

Contact: FARM SHOW Followup, Cletus Clement, RR 2, Box 133, St. Anne, Ill. 60964 (ph 815 427-6602).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.