1997 - Volume #21, Issue #2, Page #33

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

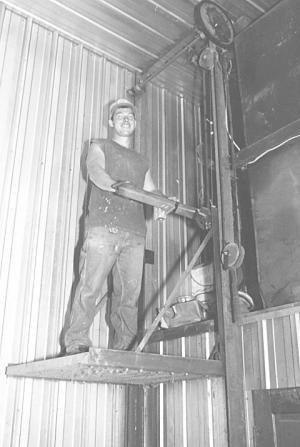

Handy Shop Elevator

|

"It'll hold two people who weigh 200 lbs. apiece, with plenty of capacity left over to handle parts and equipment. It'll hold probably 600 lbs. altogether.

"It consists of a 3-ft. sq. lift platform with an angle iron frame with 2-in. boards bolted on. It slides up and down on a frame made from two 15-ft. lengths of T-beam secured to the wall. Angle iron is fitted to the inside of the T-beam flanges to serve as a track for the lift to ride in. Two sealed ball bearings mount underneath the platform on either side to run in the angle iron, while two more sealed ball bearings mount on top to run on the back side of the T-beams.

"A big 50-tooth sprocket off an old auger and a smaller 7-tooth dia. sprocket be-low it serve as the gear reduction drive for a 1-in. dia. cross shaft at top of the frame. Spools attached to both ends of the shaft wind 1/8-in. winch cable to raise and lower the lift.

"The elevator is powered by a 3/4 hp electric motor that drives the big pulley. The elevator is equipped with a spring-loaded brake that applies or releases pressure on the pulley with a solenoid wired into the electric motor.

"The elevator is operated from a waste-high, push-button control arm. Power cable is wound around a pulley attached to the up-per T-beam and a weighted pulley below it so it raises and lowers with the lift without tangling."

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.