Automatic Trip-Bucket Feed System

✖  |

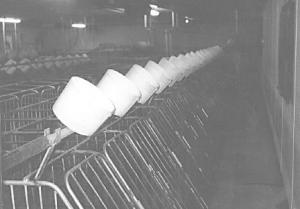

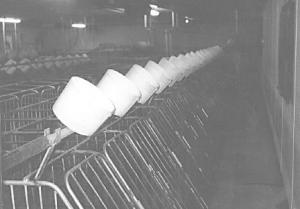

Kimmy Kooiker, Sheldon, Iowa, got tired of hand feeding sows in a total confinement gestation facility that he built a few years ago. He didn't want to spend the money for an automated feeding system so he came up with his own automatic "trip-bucket" feeding system.

Plastic buckets mounted over each stall and attached to a galvanized steel pipe that extends the length of the stalls are used to hold feed. By pulling on a handle at the end of the pipe Kooiker can dump feed from all the buckets into open troughs in front of the stalls.

He welded steel brackets over every fourth stall to support the 1 1/4-in. dia. pipe and also welded a steel handle onto the end of the pipe at the center of the building. To support the buckets he bent 16-in. lengths of flat iron at right angles, welded them onto the pipe, and bolted the buckets on. Each bucket holds about 6 lbs. of feed.

Kooiker set up the system on four rows of stalls with all the handles located next to alleys that run crosswise at the center of the building.

"It really makes feeding easy. All I have to do is walk into the building and trip the handles. Within 30 seconds, all the sows are fed and all is quiet. After I'm done feeding, I take a feed cart down each aisle and scoop feed into each bucket for the next feeding. I got the plastic white buckets free from an ice cream company in our area. My total cost was about $480."

Contact: FARM SHOW Followup, Kimmy Kooiker, 4741 360th St., Sheldon, Iowa 51201 (ph 712 324-2972).

Click here to download page story appeared in.

Click here to read entire issue

Automatic Trip-Bucket Feed System HOG EQUIPMENT & IDEAS Hog Equipment & Ideas (351) 20-5-36 Kimmy Kooiker, Sheldon, Iowa, got tired of hand feeding sows in a total confinement gestation facility that he built a few years ago. He didn't want to spend the money for an automated feeding system so he came up with his own automatic "trip-bucket" feeding system.

Plastic buckets mounted over each stall and attached to a galvanized steel pipe that extends the length of the stalls are used to hold feed. By pulling on a handle at the end of the pipe Kooiker can dump feed from all the buckets into open troughs in front of the stalls.

He welded steel brackets over every fourth stall to support the 1 1/4-in. dia. pipe and also welded a steel handle onto the end of the pipe at the center of the building. To support the buckets he bent 16-in. lengths of flat iron at right angles, welded them onto the pipe, and bolted the buckets on. Each bucket holds about 6 lbs. of feed.

Kooiker set up the system on four rows of stalls with all the handles located next to alleys that run crosswise at the center of the building.

"It really makes feeding easy. All I have to do is walk into the building and trip the handles. Within 30 seconds, all the sows are fed and all is quiet. After I'm done feeding, I take a feed cart down each aisle and scoop feed into each bucket for the next feeding. I got the plastic white buckets free from an ice cream company in our area. My total cost was about $480."

Contact: FARM SHOW Followup, Kimmy Kooiker, 4741 360th St., Sheldon, Iowa 51201 (ph 712 324-2972).

To read the rest of this story, download this issue below or click

here to register with your account number.