1993 - Volume #17, Issue #5, Page #02

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

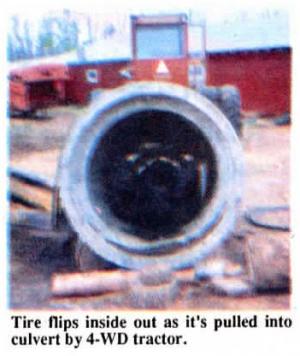

Giant Culvert Turns Tires Inside Out

|

|

Norman Westerlund uses a chain saw to cut off the bead on one side of tire and to cut four slits in the bead on the other side. He then places the side of the tire without a bead against one end of the 42-in. dia., 8-ft. long culvert. A 30-in. wheel rim is set against the beaded side of the tire, held in place by four 2-ft. chains with grab hooks that are inserted into the slits on the bead. A large eye-hook is bolted to the middle of the rim. Westerlund attaches a chain to the I-hook and uses his Versatile to pull the rim and tire through the culvert. The wheel rim forces the beaded side of the tire through first, turning the tire completely inside out by the time it reaches the other end of the culvert.

"It works good and doesn't cost much to set up," says Westerlund, who has a beef cow-calf operation. "We got the idea be-cause we didn't want to spend the money to have someone else do the job for us. A local tire turning operation wanted $20 to $25 apiece to turn tires into feedbunks. We needed 15 tires turned so we decided to save that money. We already had some culverts around that we'd bought for drainage ditches. We set one end of the culvert up on a wood block to make it easier to center the tire on the culvert. It takes quite a bit of power to pull the tires through. The key is to pull steady. We can turn about six tires an hour. The tires pull easiest when the weather is warm, but we've had no trouble turning them at temperatures down to 40 degrees.

"The culvert should be 6 to 8 in. bigger in diameter than the tire bead. We've turned 18.4 by 30, 34, and 38 tires. We use a 48-in. culvert to turn 38-in. tires because it takes less power than using the 42-in. culvert. The 30-in. wheel rim we use is off an old Farmall F-12 tractor. However, any size rim could be used as long as it fits inside the culvert. The rim is necessary to keep the tire round as it's pulled through the culvert. We tried pulling tires without the rim, but one side of the tire tended to pull ahead cif the other which kept the entire tire from turning in-side out. We use a D7 Caterpillar with dozer blade to keep the culvert from sliding as the tire is pulled through."

Contact: FARM SHOW Followup, Norman Westerlund, Glen Rt., Box 202, Aitkin, Minn. 56431 (ph 612 684-2358).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.