Built-From-Scratch 21-Bale Accumulator

"To my knowledge, there's never been anything like it on the market," says Curt Richards, Rolling Hills, Alberta, about his totally automatic, built-from-scratch bale accumulator that lays down flat stacks of 21 bales at a time, all laying on their sides so bale strings are up off the ground. What's more, Richards also made his own grapple attachment for his front-end loader to handle the stacks.

He built the equipment in his shop last winter using about $2,500 worth of new materials, with everything else coming off his scrap pile. He didn't get to see if the system actually worked until he got out to the field with his Deere 466 baler this summer.

"After a few adjustments, it worked out exactly as I designed it without reducing the capacity of the baler at all. It saves us a tremendous amount of time handling bales," says Richard. "I plan to build another accumulator next winter since we need two balers for our operation."

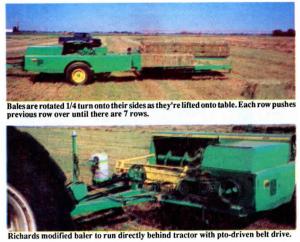

The accumulator attaches to the back of the baler and rides on a single castor fitted with dual wheels. Bales exit the bale chamber onto a small table that holds three bales end-to-end. When the third bale is pushed onto the table, a lever is tripped, automatically triggering a hydraulic cylinder that lifts the bales up onto the main table. Bales are rotated 1/4 turn onto their sides as they're lifted onto the table. Each row pushes the previous row over until there are 7 rows. A buzzer sounds in the cab when the accumulator is full and the operator trips the main table from the cab, dumping all 21 bales together on the field.

All bale handling is done with Richards' home-built grapple that mounts over the bucket on his front-end loader. He can haul 300 bales at a time back to the stackyard on his trailers.

One reason no one has manufactured a 21-bale flat stacker in the past is that the stack gets in the way of the tractor and baler after it's dropped in the field. Richards got around that problem by modifying his Deere baler so it trails directly behind the tractor, with the tractor straddling the windrow.

"This was accomplished with a pto-driven double belt drive mounted on a frame at the front of the baler. I also equipped the baler with a belt-driven hydraulic pump and reservoir tank so the baler is completely self-contained. A double pulley mounts directly over the tongue of the baler. A double belt runs from there to a pulley mounted on the baler's pto input shaft. A belt off that pulley drives the hydraulic pump," notes Richards.

"The baler is easier to operate now with the tractor directly over the swath and the accumulator has no adverse affect at all on our baling operation. Bales can be handled quicker and put into a stack that's superior to what we used to get with our New Holland stacker," says Richards.

One of the trickiest parts of building the new bale-handling system was making the grapple teeth. He cut them out of flat iron and then heated them before bending them around a jig.

Contact FARM SHOW Followup, Curtis Richards, Box 33, Rolling Hills, Alberta T0J 2S0 Canada (ph 403 964-3737).

Click here to download page story appeared in.

Click here to read entire issue

Built-From-Scratch 21-Bale Accumulator HAY & FORAGE HARVESTING Bale Handling (5) 17-5-39 "To my knowledge, there's never been anything like it on the market," says Curt Richards, Rolling Hills, Alberta, about his totally automatic, built-from-scratch bale accumulator that lays down flat stacks of 21 bales at a time, all laying on their sides so bale strings are up off the ground. What's more, Richards also made his own grapple attachment for his front-end loader to handle the stacks.

He built the equipment in his shop last winter using about $2,500 worth of new materials, with everything else coming off his scrap pile. He didn't get to see if the system actually worked until he got out to the field with his Deere 466 baler this summer.

"After a few adjustments, it worked out exactly as I designed it without reducing the capacity of the baler at all. It saves us a tremendous amount of time handling bales," says Richard. "I plan to build another accumulator next winter since we need two balers for our operation."

The accumulator attaches to the back of the baler and rides on a single castor fitted with dual wheels. Bales exit the bale chamber onto a small table that holds three bales end-to-end. When the third bale is pushed onto the table, a lever is tripped, automatically triggering a hydraulic cylinder that lifts the bales up onto the main table. Bales are rotated 1/4 turn onto their sides as they're lifted onto the table. Each row pushes the previous row over until there are 7 rows. A buzzer sounds in the cab when the accumulator is full and the operator trips the main table from the cab, dumping all 21 bales together on the field.

All bale handling is done with Richards' home-built grapple that mounts over the bucket on his front-end loader. He can haul 300 bales at a time back to the stackyard on his trailers.

One reason no one has manufactured a 21-bale flat stacker in the past is that the stack gets in the way of the tractor and baler after it's dropped in the field. Richards got around that problem by modifying his Deere baler so it trails directly behind the tractor, with the tractor straddling the windrow.

"This was accomplished with a pto-driven double belt drive mounted on a frame at the front of the baler. I also equipped the baler with a belt-driven hydraulic pump and reservoir tank so the baler is completely self-contained. A double pulley mounts directly over the tongue of the baler. A double belt runs from there to a pulley mounted on the baler's pto input shaft. A belt off that pulley drives the hydraulic pump," notes Richards.

"The baler is easier to operate now with the tractor directly over the swath and the accumulator has no adverse affect at all on our baling operation. Bales can be handled quicker and put into a stack that's superior to what we used to get with our New Holland stacker," says Richards.

One of the trickiest parts of building the new bale-handling system was making the grapple teeth. He cut them out of flat iron and then heated them before bending them around a jig.

Contact FARM SHOW Followup, Curtis Richards, Box 33, Rolling Hills, Alberta TOJ 2S0 Canada (ph 403 964-3737).

To read the rest of this story, download this issue below or click

here to register with your account number.