2012 - Volume #36, Issue #4, Page #06

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Grass Seed Business Pays More Than Corn, Beans

|

|

|

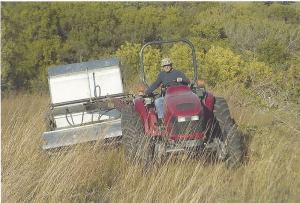

“I’ve made or modified all the equipment used for the seed operation,” Buman says. In recent years, he has turned out specialized planting equipment, seed strippers, a grass combine and a fanning mill to clean seeds smaller than the eye of a needle.

Buman describes with pride how he built his own brush-type machine for cleaning tiny grass and flower seed. He designed plastic brushes with three different sizes of bristles and brushes to gently sweep across a wire screen and dehull grass seeds. He built seed conveyors with belts powered by small electric motors. Some motors run on AC, some on DC and current modulators regulate speed. He also built a seed scalper that removes larger material from the seed.

During a recent winter, he worked 2 mos. to convert a Deere 800 windrower into a hydrostatic-powered windrower. He used hydraulic parts from two self-propelled sprayers, a hydro pump from a skid steer, and controls from an IH combine. “Trying to find answers to questions was my toughest challenge,” Buman says. “I talked to hydraulics specialists, but since I wasn’t working on something they produced, it was very difficult to get usable answers. A couple guys didn’t know if the machine would fly or crawl with certain parts.” Eventually through trial and error he made the hydraulic system work. Now his 10-ft. custom-built swather runs like a zero-turn mower. “The right lever runs the right wheel and the electric switch raises and lowers the head. The left lever runs the left wheel and the electric switch lifts and lowers the reel. The swather has a slant six Chrysler motor that’s more than a little temperamental. Still, Buman says the rig works like it’s supposed to, and that’s the main thing.

“This grass business is very specialized.” Buman says. “We have intense hand labor for a couple months. In less than a week we plant 40,000 sets. We have weeding and pest control, and then we have harvest. Sometimes it’s too hot and dry, other times it’s too cool and wet.” However, with seed that sells for $7 to $200 per lb., Buman says the money is worth it. Last year he had three 30-ft. by 100- ft. plots produce 16 lbs. “I made more than $16,000 from a little under 1/3rd of an acre,” he says. Other plots produced 400 lbs. that Buman sold for $125 per lb.

Buman says that even though the business is labor-intensive, he really enjoys it. “I build equipment in mid-winter, but then I’m back in the greenhouse setting new plants or working in the shop.”

Contact: FARM SHOW Followup, Bill Buman, 918 Road M16, Harlan, Iowa 51537 (ph 712 744-3675; bumanwj@fmctc.com).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.