2006 - Volume #30, Issue #3, Page #38

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Used Oil Pumping System

|

|

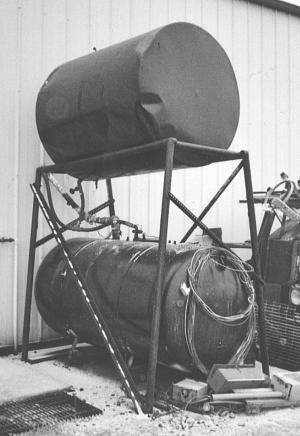

Gary Elston, Mulvane, Kansas, used salvage materials to come up with an automatic oil pumping system in his shop. It uses an electric motor and a gear pump pump to automatically deliver used oil from his tractors to an indoor container and then to a pair of 300-gal. storage tanks outside the shop.

"We burn the oil in a furnace to heat our shop," says Elston.

Used oil is sucked from a portable oil pan through a 15-ft. long hose to a "T" line inside a small plastic barrel cut lengthwise in half. The "T" line is hooked up to a gear pump that's driven by a small electric motor. The oil is delivered into a nearby 55-gal. barrel with a lid cut into its top. A section of perforated bin flooring, mounted 6 in. above the bottom of the barrel, serves as a screen when draining used oil out of filters and small oil pans.

Whenever the 55-gal. barrel gets full, Elston opens an in-line valve to suck oil from the barrel through a hose that leads outside to the two storage tanks.

"It lets us pump used oil straight from the oil pan into storage tanks instead of having to carry it in buckets," says Elston. "A switch that mounts on a control panel inside the half barrel is used to turn the electric motor on or off. To make the portable oil pan we cut the bottom six inches off a 55-gal. metal barrel, then cut a hole in one side and attached a 1-in. dia. hose to it."

Contact: FARM SHOW Followup, Gary Elston, 427 Franklin Ave., Mulvane, Kansas 67110 (ph 316 777-1234).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.